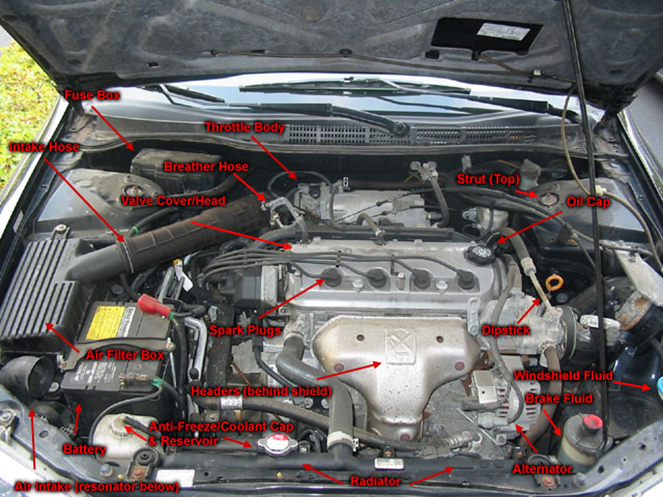

Diagram Of Car Parts Under The Hood

So, you're ready to dive under the hood and get a better understanding of what's what? Smart move! Knowing your way around your engine bay is crucial for everything from basic maintenance to diagnosing more complex issues. This article will act as your guide to interpreting a diagram of car parts under the hood, helping you navigate that maze of hoses, wires, and components with confidence. We'll break down the key elements, explain how they work together, and even offer some real-world troubleshooting tips.

Purpose: Why Understand the Under-Hood Diagram?

Let's be honest, staring at a diagram of your engine bay can feel overwhelming at first. But trust me, the payoff is huge. Understanding this diagram is vital for several reasons:

- Repair and Maintenance: Identifying parts becomes exponentially easier. Need to replace a worn-out hose? Find the exact location of the coolant reservoir? The diagram is your map.

- Troubleshooting: When your car throws a code or exhibits unusual behavior, a diagram helps you pinpoint potential culprits. Is the mass airflow sensor malfunctioning? The diagram will show you exactly where it's located.

- Modifications: Planning to install aftermarket parts? Knowing where everything is situated will help you avoid damaging existing components and ensure a clean, professional install.

- Learning and Understanding: Beyond repairs, simply understanding how your car *works* is empowering. A diagram is an excellent tool for visualizing the complex systems that keep you moving.

- Safety: Knowing the location of hazardous components – like the high-voltage ignition system – allows you to work safely under the hood.

Key Specs and Main Parts: The Engine Bay Essentials

While the specific layout varies depending on your vehicle's make, model, and engine type, some key components are almost always present. Here's a rundown of the main players, along with some technical terms you should know:

- Engine Block: The heart of the car, housing the cylinders, pistons, crankshaft, and other critical internal components.

Intake System

- Air Filter: Cleans the air entering the engine.

- Mass Airflow Sensor (MAF): Measures the amount of air entering the engine; crucial for calculating the correct fuel mixture. A faulty MAF sensor is a common cause of poor fuel economy and rough idling.

- Throttle Body: Controls the amount of air entering the intake manifold.

- Intake Manifold: Distributes air to the cylinders.

Fuel System

- Fuel Injectors: Spray fuel into the cylinders.

- Fuel Rail: Supplies fuel to the injectors.

- Fuel Pressure Regulator: Maintains consistent fuel pressure in the fuel rail.

Cooling System

- Radiator: Dissipates heat from the coolant.

- Coolant Reservoir (Overflow Tank): Stores excess coolant.

- Water Pump: Circulates coolant through the engine and radiator.

- Thermostat: Regulates engine temperature by controlling coolant flow.

Electrical System

- Battery: Provides electrical power to start the engine and operate electrical components.

- Alternator: Charges the battery and powers electrical systems when the engine is running.

- Starter Motor: Cranks the engine to start it.

- Ignition Coils: Provide the high voltage needed to ignite the air-fuel mixture in the cylinders.

- Engine Control Unit (ECU): The "brain" of the engine, controlling fuel injection, ignition timing, and other critical functions. Modern ECUs use sophisticated algorithms to optimize engine performance and emissions.

Exhaust System

- Exhaust Manifold: Collects exhaust gases from the cylinders.

- Catalytic Converter: Reduces harmful emissions.

- Oxygen Sensors (O2 Sensors): Monitor the oxygen content in the exhaust gases to help the ECU optimize fuel mixture.

Other Important Components

- Power Steering Pump: Provides hydraulic pressure to assist steering.

- Air Conditioning Compressor: Compresses refrigerant for the air conditioning system.

- Brake Master Cylinder: Supplies hydraulic pressure to the brake system.

Symbols: Decoding the Diagram

Under-hood diagrams aren't just pictures; they're packed with symbols that convey important information. Here's a breakdown of what to look for:

- Lines: Different line types often represent different types of hoses or wires. Solid lines might indicate fuel lines, while dashed lines could represent vacuum hoses.

- Colors: Wire colors are critical for electrical work. Always refer to the wiring diagram specific to your vehicle.

- Icons: Small icons represent specific components, such as fuses, relays, and sensors.

- Abbreviations: Diagrams are often full of abbreviations. Common ones include: MAF (Mass Airflow Sensor), ECT (Engine Coolant Temperature), TPS (Throttle Position Sensor), and IAC (Idle Air Control).

How It Works: The Interconnected Systems

The true power of the diagram lies in showing you how all these components are interconnected. The intake system draws air in, the fuel system delivers fuel, and the ECU orchestrates the whole process to create combustion. The cooling system prevents overheating, and the exhaust system removes waste gases. A malfunction in one system can often affect others, which is why a holistic understanding is so valuable. For example, a vacuum leak (represented by a broken or disconnected line in the diagram) can throw off the air-fuel mixture, causing the engine to run poorly.

Real-World Use: Basic Troubleshooting Tips

Okay, let's put this knowledge into practice. Imagine your car is idling roughly. Here’s how you might use a diagram:

- Consult the Diagram: Locate the Idle Air Control (IAC) valve. This valve regulates airflow to the engine at idle.

- Visual Inspection: Check the hoses connected to the IAC valve for cracks or leaks.

- Electrical Connections: Inspect the wiring harness connected to the IAC valve for damage or loose connections.

- Testing (Advanced): If a visual inspection doesn't reveal anything, you might use a multimeter to test the IAC valve's resistance, comparing your readings to the manufacturer's specifications.

By using the diagram to guide your inspection, you're far more likely to pinpoint the problem quickly and efficiently.

Another example, if you get a check engine light and the code reader indicates a problem with the Oxygen Sensor. Using the diagram, you can quickly locate the O2 sensor in the exhaust manifold or downstream from the catalytic converter and inspect it for damage or loose connections.

Safety: Knowing the Risky Components

Working under the hood can be dangerous if you're not careful. Here are some key safety considerations:

- High Voltage: The ignition system components (ignition coils, spark plugs) carry extremely high voltage. Never touch these components while the engine is running or the ignition is on.

- Hot Surfaces: The exhaust manifold and engine block can reach very high temperatures. Allow the engine to cool down completely before working near these areas.

- Moving Parts: Keep your hands, clothing, and tools clear of moving parts, such as the serpentine belt and cooling fan.

- Fuel Leaks: Fuel is highly flammable. If you smell gasoline, immediately ventilate the area and eliminate any potential ignition sources (sparks, open flames).

- Battery: Disconnect the negative battery terminal before working on any electrical components to prevent shorts and potential damage.

- Cooling System: Never remove the radiator cap when the engine is hot. The cooling system is pressurized, and hot coolant can spray out, causing severe burns.

Safety First! Always prioritize safety when working on your car. If you're unsure about a procedure, consult a qualified mechanic.

Armed with this knowledge and the downloadable diagram, you're well on your way to becoming a more confident and capable DIY mechanic. Good luck, and remember to work safely!

We have the complete Under the Hood Diagram file ready for you. Download it now and start exploring your engine bay with confidence!