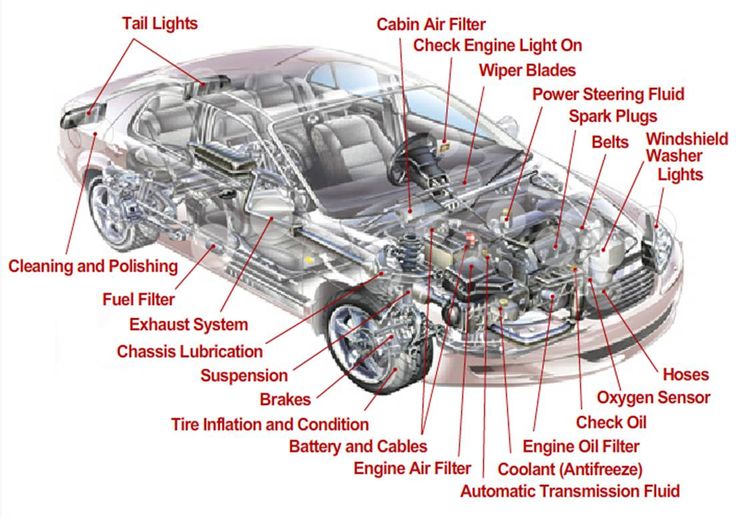

Diagram Of The Underside Of A Car

Understanding the undercarriage of your car is crucial for anyone who wants to perform their own maintenance, modifications, or even just diagnose potential problems. This guide provides a detailed breakdown of the key components found underneath your vehicle, explaining their function, how they interact, and how to identify common issues. We aim to empower you with the knowledge needed to tackle DIY repairs safely and effectively.

Purpose of Understanding the Underside

Why bother learning about what's underneath your car? The answer is multifaceted. First, it empowers you to perform basic maintenance tasks like oil changes, brake inspections, and exhaust system checks. Second, it aids in diagnosing problems. A strange noise coming from the suspension? Knowing the components helps you pinpoint the source. Third, it's essential for modifications. Planning to upgrade your exhaust? Understanding its routing and connections is critical. Finally, it promotes safety. Identifying potential hazards like corroded brake lines allows you to address them before they become dangerous. Ultimately, understanding the underside of your car saves you money, increases your confidence, and promotes safer driving.

Key Specs and Main Parts

The undercarriage of a car is a complex network of interconnected systems. Let's break down the major components:

Drivetrain Components

The drivetrain is responsible for transmitting power from the engine to the wheels. Key components include:

- Engine Oil Pan: (Usually at the very front) Holds the engine's oil supply. Look for signs of leaks (oil stains).

- Transmission: (Located behind the engine) Transmits power from the engine to the driveshaft or axles. Automatic transmissions have pan and filter that need periodic maintenance.

- Driveshaft: (In rear-wheel-drive vehicles) Connects the transmission to the differential. Subject to wear and tear on the universal joints (U-joints).

- Differential: (Located at the rear axle) Divides power between the rear wheels, allowing them to rotate at different speeds during turns.

- Axles: (Connect the differential to the wheels) Transfer power from the differential to the wheels. Constant velocity (CV) joints on front-wheel-drive cars are a common failure point.

- Exhaust System: (Runs the length of the car) Carries exhaust gases away from the engine. Components include:

- Exhaust Manifold: Attached to the engine.

- Catalytic Converter: Reduces harmful emissions.

- Muffler: Reduces exhaust noise.

- Tailpipe: The final exit point for exhaust gases.

Suspension Components

The suspension system provides a smooth ride and maintains tire contact with the road. Key components include:

- Control Arms: Connect the wheels to the chassis, allowing them to move up and down.

- Struts/Shocks: Dampen suspension movement, preventing bouncing. Leaking fluid indicates a failing strut/shock.

- Springs: Support the weight of the vehicle and absorb bumps.

- Sway Bar (Anti-Roll Bar): Reduces body roll during cornering. Connected to the suspension components by end links.

- Tie Rods: Connect the steering rack to the steering knuckles, allowing you to steer the car.

- Ball Joints: Allow the suspension components to move freely. Prone to wear and can cause clunking noises.

Braking System Components

The braking system is essential for stopping the vehicle. Key components include:

- Brake Lines: Carry brake fluid from the master cylinder to the brake calipers. Look for signs of corrosion or leaks.

- Brake Calipers: Squeeze the brake pads against the rotors to slow the vehicle.

- Brake Rotors: The rotating discs that the brake pads clamp onto.

Fuel System Components

The fuel system delivers fuel to the engine. Key components include:

- Fuel Tank: Stores fuel.

- Fuel Lines: Carry fuel from the fuel tank to the engine.

Other Important Components

- Frame/Unibody: The structural backbone of the vehicle. Look for signs of rust or damage.

- Heat Shields: Protect components from exhaust heat.

Symbols, Lines and Colors

Technical diagrams use a standardized set of symbols, lines, and colors to represent different components and systems. Understanding these conventions is critical for interpreting the diagram effectively.

- Solid Lines: Typically represent rigid components like frame rails, control arms, and exhaust pipes.

- Dashed Lines: Often indicate flexible components like hoses and wiring harnesses or represent parts that are behind other parts.

- Colors: Different colors can represent different systems. For example:

- Red: Usually indicates the brake system (brake lines, calipers).

- Blue: Might represent the fuel system (fuel lines).

- Green: Could indicate power steering lines.

- Arrows: Show the direction of fluid flow (e.g., in brake lines or fuel lines).

- Geometric Shapes: Symbols like circles, squares, and triangles are used to represent specific components like sensors, connectors, and mounting points. A legend should always accompany the diagram to explain these symbols.

How It Works

The systems under your car work together in a coordinated manner. The engine generates power, which is transmitted through the drivetrain to the wheels. The suspension system keeps the tires in contact with the road, while the braking system allows you to stop safely. The fuel system provides the necessary fuel for the engine to run. Each system relies on the others for optimal performance. For example, worn suspension components can affect braking performance and tire wear. A properly functioning exhaust system ensures efficient engine operation. Understanding these interdependencies is key to effective troubleshooting.

Real-World Use – Basic Troubleshooting Tips

Here are some basic troubleshooting tips based on visual inspection of the undercarriage:

- Oil Leaks: Check the engine oil pan, transmission, and around seals. Look for dark, oily residue.

- Coolant Leaks: Look for puddles of green or orange fluid under the car, especially near the radiator hoses.

- Brake Fluid Leaks: Inspect brake lines, calipers, and wheel cylinders for leaks. Brake fluid is clear or amber in color.

- Exhaust Leaks: Listen for hissing or roaring sounds coming from the exhaust system. Check for rust or cracks in the pipes, catalytic converter, and muffler.

- Suspension Noises: Clunking, squeaking, or rattling noises can indicate worn ball joints, tie rod ends, struts, or sway bar links.

- CV Joint Problems: Clicking or popping noises during turns can indicate worn CV joints. Look for grease leaking from the CV joint boots.

Safety – Highlight Risky Components

Working under a car can be dangerous if proper precautions are not taken. Here are some critical safety considerations:

- Always use jack stands: Never rely solely on a jack to support the weight of the vehicle.

- Wear safety glasses: Protect your eyes from debris and fluids.

- Disconnect the battery: This prevents accidental electrical shocks.

- Be aware of hot components: Exhaust systems can remain hot for a long time after the engine has been turned off.

- Brake System: The brake system is critical for safety. If you are unsure about any aspect of brake repair, consult a qualified mechanic. Improper brake work can lead to serious accidents. Always properly bleed the brakes after opening the system.

- Fuel System: Fuel is highly flammable. Never work on the fuel system near open flames or sources of ignition. Relieve fuel pressure before disconnecting fuel lines.

- Suspension Springs: Be extremely careful when working with suspension springs. They are under considerable tension and can cause serious injury if released suddenly. Use proper spring compressors when necessary.

We have a high-resolution diagram available for download, detailing the undercarriage components discussed above. This diagram will serve as a valuable visual aid for your DIY projects and troubleshooting endeavors. Please find the link below to access the file.