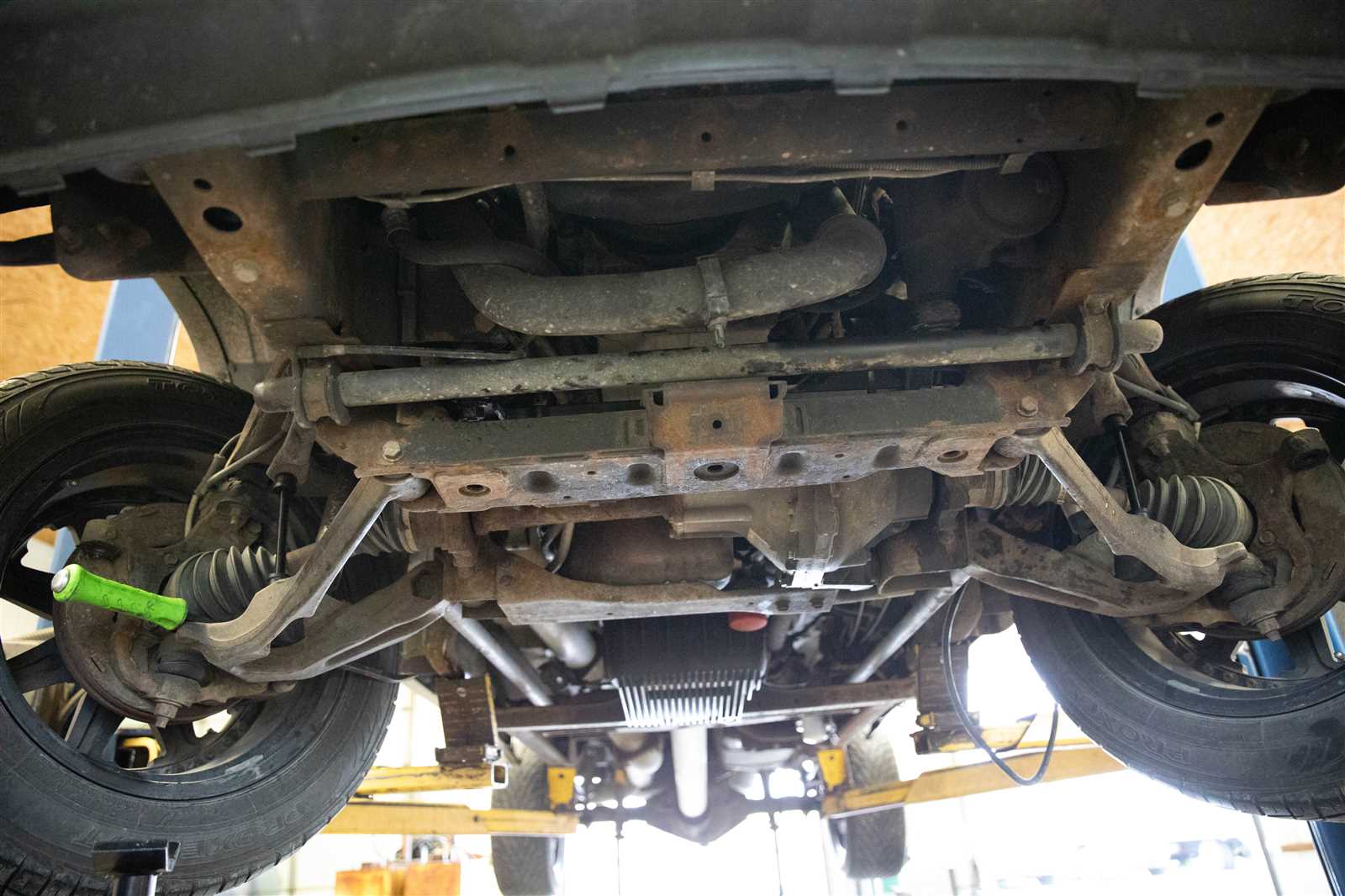

Dodge Ram 1500 Front Suspension Diagram

Understanding the front suspension of your Dodge Ram 1500 is crucial for everything from routine maintenance to complex repairs and modifications. This diagram acts as a roadmap, guiding you through the intricate system that keeps your truck riding smoothly and handling predictably. Whether you're diagnosing a mysterious clunk, planning a lift kit installation, or simply expanding your automotive knowledge, this detailed guide will help you decipher the complexities of your Ram's front suspension.

Purpose of the Front Suspension Diagram

The primary purpose of a front suspension diagram is to provide a visual representation of the system's components and their relationships. It's a tool used for:

- Diagnosis: Identifying the location of a malfunctioning part.

- Repair: Guiding the disassembly and reassembly process.

- Modification: Planning and executing aftermarket upgrades like lift kits or performance shocks.

- Learning: Understanding the overall design and function of the suspension system.

Having a readily available diagram, especially one specific to your model year, saves time and reduces the risk of errors during any suspension-related work. We have that diagram available for you to download at the end of the article.

Key Specifications and Main Parts

The Dodge Ram 1500 typically employs an independent front suspension (IFS) system, most commonly a double wishbone design. Knowing the specific year of your truck is important, as there can be subtle variations. Here are the key components you'll typically find in the diagram:

Upper and Lower Control Arms

These are essentially A-shaped arms that connect the wheel hub to the vehicle's frame. The upper control arm is usually shorter than the lower. They allow the wheel to move up and down while maintaining proper alignment. They pivot on bushings, allowing for movement and vibration absorption.

Coil Springs

These provide the primary suspension support, absorbing bumps and maintaining ride height. They are located between the lower control arm and a mounting point on the frame.

Shock Absorbers (Dampers)

These control the rate at which the suspension compresses and rebounds. They work by forcing hydraulic fluid through small orifices, converting kinetic energy into heat. Without shocks, the truck would bounce uncontrollably after hitting a bump. They are sometimes combined with the coil spring in a single unit called a coilover.

Steering Knuckle (Spindle)

This is the pivoting point for the wheel hub assembly. It connects to the control arms via ball joints and houses the wheel bearing and brake components.

Ball Joints

These are spherical bearings that allow the steering knuckle to move up and down and side to side. They connect the steering knuckle to the upper and lower control arms and are critical for steering control. They are wear items and must be inspected regularly.

Tie Rods

These connect the steering rack to the steering knuckles. When you turn the steering wheel, the steering rack moves, pushing or pulling the tie rods to steer the wheels.

Sway Bar (Anti-Roll Bar)

This torsion bar connects the left and right sides of the suspension. It helps to reduce body roll during cornering by transferring force from one side of the suspension to the other.

Hub Assembly and Wheel Bearing

The hub assembly is what the wheel bolts to, and the wheel bearing allows the wheel to rotate smoothly. These are typically integrated into a single unit.

Torsion Bars (On some models)

Some older Ram 1500 models might use torsion bars instead of coil springs. These are long, springy bars that are twisted to provide suspension. The torsion bar key allows for ride height adjustment.

Diagram Symbols: Understanding the Visual Language

Suspension diagrams use a variety of symbols to represent different components and connections. Understanding these symbols is crucial for interpreting the diagram correctly.

- Solid Lines: Typically represent solid parts like control arms, the frame, or the steering knuckle. The thickness of the line might indicate the size or strength of the component.

- Dashed Lines: Often indicate hidden components or lines of reference. For instance, a dashed line might represent the centerline of the vehicle or the path of a moving part.

- Arrows: Indicate the direction of movement or force. For example, arrows might show the direction of suspension travel or the direction of force applied by the shock absorber.

- Circles and Dots: Usually represent pivot points, bushings, or fasteners. A filled circle might represent a fixed pivot point, while an open circle might represent a bushing.

- Colors (if present): Some diagrams use color-coding to differentiate between different systems or materials. For example, red might indicate hydraulic lines, while blue might indicate electrical wiring (if applicable).

- Icons: Standard icons are used to represent components like coil springs, shock absorbers, and ball joints. These icons are generally consistent across different diagrams. Consult the legend of the diagram for specific symbol definitions.

How It Works: The Suspension in Action

The front suspension of your Ram 1500 is designed to isolate the vehicle's cabin from road imperfections, providing a comfortable ride and maintaining stable handling. Here's a simplified explanation of how it works:

- Bump Impact: When a wheel encounters a bump, it moves upward, compressing the coil spring (or twisting the torsion bar).

- Energy Absorption: The spring absorbs the energy of the impact, preventing it from being transmitted directly to the frame.

- Damping Control: The shock absorber restricts the rate at which the spring compresses and rebounds, preventing excessive bouncing.

- Steering Control: The ball joints and tie rods allow the wheel to move up and down and side to side while maintaining steering control.

- Roll Reduction: The sway bar helps to reduce body roll during cornering by transferring force between the left and right sides of the suspension.

This coordinated action allows the wheels to follow the contours of the road while keeping the vehicle body relatively stable.

Real-World Use: Basic Troubleshooting Tips

A suspension diagram can be invaluable when troubleshooting common suspension problems. Here are a few examples:

- Clunking Noise: Use the diagram to locate potential sources of the noise, such as worn ball joints, loose sway bar links, or failing shock absorbers. Inspect these components for play or damage.

- Excessive Bouncing: This usually indicates worn-out shock absorbers. The diagram will show you the location and mounting points of the shocks, allowing you to easily inspect them for leaks or damage.

- Uneven Tire Wear: This can be caused by misaligned suspension components, such as bent control arms or worn ball joints. The diagram can help you identify these components and check their alignment.

- Poor Handling: Worn ball joints, tie rod ends, or sway bar links can all contribute to poor handling. The diagram will show you the location of these components, allowing you to inspect them for play.

Always consult your vehicle's service manual for specific troubleshooting procedures and torque specifications.

Safety Considerations

Working on your Ram 1500's front suspension can be dangerous if proper safety precautions are not taken. Here are some critical safety tips:

- Use Jack Stands: Never work under a vehicle supported only by a jack. Always use properly rated jack stands placed on a solid, level surface.

- Compress Coil Springs Safely: Coil springs store a tremendous amount of energy and can cause serious injury if they are released suddenly. Use a properly rated coil spring compressor and follow the manufacturer's instructions carefully. Do not attempt to compress coil springs without the correct tool and knowledge.

- Be Aware of ABS Sensors: ABS (Anti-lock Braking System) sensors are often located near the suspension components. Be careful not to damage these sensors during repairs.

- Torque to Specification: Always torque all fasteners to the manufacturer's specifications. Use a torque wrench and consult your vehicle's service manual for the correct torque values.

- Consult a Professional: If you are not comfortable working on your vehicle's suspension, consult a qualified mechanic. Certain repairs, especially those involving coil spring compression or alignment, are best left to professionals.

Remember, safety is paramount. Take your time, follow the proper procedures, and don't hesitate to seek professional help if needed.

Now you're armed with the knowledge to understand your Dodge Ram 1500's front suspension. To get started on your project, or to better understand your truck, download the detailed front suspension diagram here.