F250 Rear Light Wiring Ford Tail Light Wire Colors

Understanding the rear light wiring of your Ford F250 is crucial for a variety of reasons, from simple bulb replacements to more complex modifications like adding aftermarket trailer wiring or troubleshooting electrical issues. This guide serves as a comprehensive resource for intermediate car owners, modders, and DIY mechanics looking to get a handle on their F250's rear lighting system.

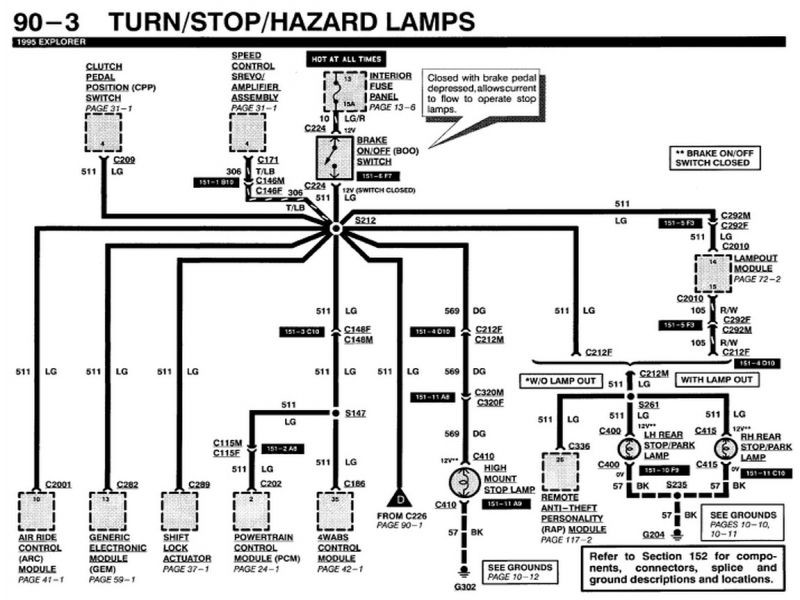

Purpose of the Wiring Diagram

Why bother diving into the world of automotive wiring diagrams? The answer is simple: they empower you. Knowing your F250's tail light wiring enables you to:

- Diagnose and Repair: Quickly identify shorts, open circuits, and other electrical faults that cause lights to malfunction.

- Perform Upgrades: Safely install aftermarket lights, trailer wiring harnesses, or other electrical accessories.

- Understand Your Vehicle: Gain a deeper understanding of how your truck's electrical system works, making you a more informed owner.

- Avoid Costly Repairs: Address minor issues before they escalate into major problems requiring expensive professional help.

Key Specs and Main Parts of the F250 Rear Lighting System

Before we jump into the wiring diagram itself, let's cover some key specifications and components you'll encounter:

- Voltage: The F250 operates on a 12-volt DC electrical system. This is standard for automotive applications.

- Bulb Types: Different bulb types are used for various functions, such as brake lights, tail lights, turn signals, and reverse lights. Common types include incandescent bulbs, LEDs (Light Emitting Diodes), and halogen bulbs. The specific bulb type varies depending on the F250 model year and trim level.

- Fuses and Relays: These are crucial safety devices that protect the electrical system from overloads and shorts. Fuses are designed to blow, interrupting the circuit and preventing damage. Relays are electrically operated switches that control high-current circuits with a low-current signal.

- Connectors: Connectors are used to join wires together, allowing for easy disconnection and reconnection. They come in various shapes and sizes and are often color-coded to identify specific circuits.

- Wiring Harness: The wiring harness is a bundle of wires that are organized and protected by a plastic sheath. It distributes electrical power and signals throughout the vehicle.

- Grounding Points: Proper grounding is essential for the electrical system to function correctly. Grounding points are locations where wires are connected to the vehicle's metal chassis, providing a return path for the electrical current.

The main parts of the rear lighting system include:

- Tail Light Assembly: The physical housing containing all the rear lights.

- Bulbs/LEDs: The light sources themselves.

- Sockets: The connectors that hold the bulbs and provide electrical connection.

- Wiring Harness: The bundle of wires connecting all the lights.

- Connectors: The points where the wiring harness connects to the main vehicle wiring.

Understanding Wiring Diagram Symbols

A wiring diagram is a symbolic representation of an electrical circuit. Here's a breakdown of common symbols you'll find in an F250 rear light wiring diagram:

- Lines: Solid lines represent wires. Dashed lines may indicate shielded wires or grounds. Line thickness doesn't necessarily represent wire gauge.

- Colors: Each wire is typically color-coded to help identify its function. Common colors include:

- Brown: Usually for tail lights.

- Green: Often for right turn signals.

- Yellow: Commonly for left turn signals and brake lights.

- White: Almost always ground.

- Black: Power or ground, check diagram for specific use.

- Circles: Often represent connectors or junction points.

- Rectangles: Can represent components like relays, fuses, or control modules.

- Ground Symbol: Looks like an upside-down triangle or a series of horizontal lines, indicating a connection to the vehicle's chassis ground.

- Bulb Symbol: A circle with a filament inside represents a light bulb.

Important Note: Wiring diagrams may vary slightly depending on the F250's model year, trim level, and specific options. Always refer to the diagram that corresponds to your exact vehicle configuration.

How It Works: A Simplified Explanation

The rear lighting system operates based on simple principles. When you turn on your headlights, a signal is sent to the tail light relay, which then provides power to the tail light circuit. When you press the brake pedal, a signal is sent to the brake light switch, which activates the brake lights. When you activate the turn signal lever, the flasher module sends an intermittent signal to the appropriate turn signal lights.

The wiring diagram illustrates how these signals are routed through the various components of the system. For example, the diagram will show how the brake light switch is connected to the brake lights, and how the turn signal switch is connected to the turn signal lights. Understanding this signal flow is crucial for troubleshooting electrical problems.

Real-World Use: Basic Troubleshooting Tips

Here are some common problems and troubleshooting steps using the wiring diagram:

- Problem: One or more rear lights are not working.

- Step 1: Check the bulbs. Are they burned out? Replace if necessary.

- Step 2: Check the fuses. Use the diagram to locate the correct fuse for the affected lights. If the fuse is blown, replace it. If it blows again immediately, there's likely a short circuit in the wiring.

- Step 3: Use a multimeter to check for voltage at the bulb socket. If there's no voltage, trace the wiring back to the fuse box or relay, using the diagram as a guide. Look for breaks, loose connections, or corrosion.

- Step 4: Check the ground connection. A bad ground can cause all sorts of electrical problems. Make sure the ground wire is securely attached to the vehicle's chassis.

- Problem: The turn signals are flashing too fast (hyper-flashing).

- Step 1: This usually indicates a burned-out bulb in the turn signal circuit. Check all turn signal bulbs (front and rear) and replace any that are faulty.

- Step 2: If all bulbs are good, the flasher relay might be defective. Replace the flasher relay.

- Problem: Trailer lights are not working.

- Step 1: Check the trailer light fuses in the truck. Refer to the owner's manual or wiring diagram to locate the correct fuses.

- Step 2: Check the trailer connector on the truck. Ensure that the connector is clean and free of corrosion.

- Step 3: Use a multimeter to check for voltage at the trailer connector pins. If there's no voltage, trace the wiring back to the fuse box or relay, using the diagram as a guide.

Safety Precautions

Working with automotive electrical systems can be dangerous. Always take the following precautions:

- Disconnect the Battery: Before working on any electrical circuit, disconnect the negative terminal of the battery to prevent accidental shocks or shorts.

- Use Proper Tools: Use insulated tools and wear safety glasses to protect yourself from injury.

- Be Aware of Airbags: Airbag systems contain high-voltage components that can be dangerous. Refer to the service manual for specific instructions on disabling the airbag system before working in its vicinity.

- Fuses Protect the System: Never replace a fuse with one of a higher amperage rating. This can overload the circuit and cause a fire.

High-Risk Components: Certain components, like the flasher module and relays, can contain capacitors that store electrical charge even after the battery is disconnected. Discharge these components properly before handling them.

By understanding the wiring diagram and following these safety precautions, you can confidently tackle many rear light repairs and modifications on your Ford F250.

We have a detailed, downloadable wiring diagram available for you. Use it as a reference to guide you through your repairs and projects. Remember to always prioritize safety and consult a qualified mechanic if you're unsure about any aspect of the electrical system.