Ford 3 Pin Alternator Wiring Diagram

The Ford 3-pin alternator wiring diagram is an essential resource for anyone working on a charging system in a classic or slightly older Ford vehicle. Understanding this diagram isn't just about fixing a broken alternator; it's about gaining a deeper knowledge of your car's electrical system, enabling you to perform upgrades, diagnose issues accurately, and prevent future problems. Whether you're dealing with a faulty charging system, planning an engine swap, or simply want to expand your automotive knowledge, mastering this diagram is a valuable skill.

Purpose of Understanding the 3-Pin Alternator Wiring Diagram

This diagram serves multiple crucial purposes:

- Repair and Diagnosis: It allows you to pinpoint the exact cause of charging system failures, from a bad connection to a faulty voltage regulator.

- Modification and Upgrades: If you're upgrading your alternator or performing an engine swap, the diagram ensures correct wiring and prevents electrical damage.

- Understanding System Function: By tracing the circuits, you gain a comprehensive understanding of how the alternator, battery, and other components interact.

- Troubleshooting Starting Issues: A poorly charging alternator can mimic a bad battery, so understanding the wiring helps differentiate the root cause.

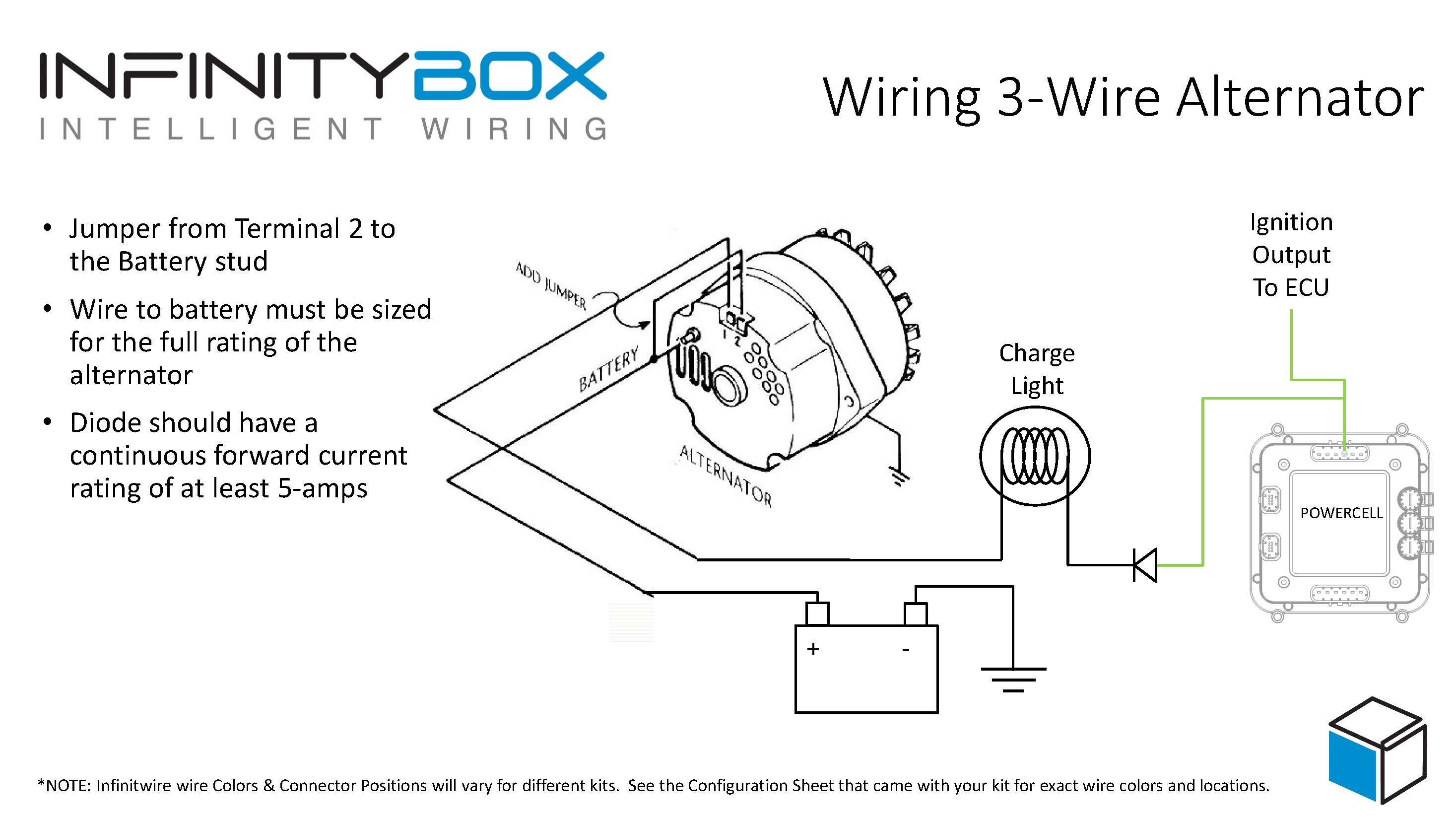

Key Specs and Main Parts of a 3-Pin Alternator System

The 3-pin alternator setup, commonly found in older Ford models, is relatively straightforward. The key components are:

- Alternator: The heart of the charging system. Converts mechanical energy from the engine into electrical energy. Typically rated in Amps (e.g., 60A, 75A, 100A) indicating its maximum output.

- Battery: Stores electrical energy and provides power to start the engine and run accessories. Usually a 12V lead-acid battery.

- Voltage Regulator: Controls the alternator's output voltage to prevent overcharging the battery. Can be internal or external to the alternator.

- Wiring Harness: Connects all the components with specific wires for voltage sensing, stator output, and ignition activation.

- Ammeter/Voltmeter: Provides a visual indication of the charging system's performance. An ammeter measures current flow, while a voltmeter measures voltage.

The 3 pins on the alternator typically correspond to the following functions:

- Pin 1 (Stator or "S"): Connects to the stator windings *inside* the alternator. This provides a signal used by the voltage regulator to determine the alternator's load. It's not a high-current wire but an information wire.

- Pin 2 (Ignition or "I"): This wire receives power when the ignition is turned to the "on" position. It activates the alternator's voltage regulator and allows it to start charging.

- Pin 3 (Voltage Sense or "A"): This wire connects directly to the battery positive terminal (or a point very close to it) and is used by the voltage regulator to sense the battery's voltage. This allows the regulator to adjust the alternator's output to maintain the correct charging voltage (typically around 13.8-14.4V). This wire is often thicker than the "S" and "I" wires.

Symbols in the Wiring Diagram

Understanding the symbols is crucial to interpreting the diagram effectively. Here's a breakdown of common symbols:

- Solid Lines: Represent wires. The thickness of the line *may* indicate wire gauge, but it's best to confirm with the wire gauge specification provided (if any) in the diagram.

- Dashed Lines: Often represent grounds or shielded wires.

- Circles: Can represent connectors, fuses, or relays.

- Rectangles: Typically represent components like the alternator, voltage regulator, or battery.

- Ground Symbol (usually three horizontal lines descending in size): Indicates a connection to the vehicle's chassis, providing a path for current to return to the battery.

- "S," "I," and "A": Labels for the stator, ignition, and voltage sense wires, respectively.

Color Coding: Color-coded wires are used to easily identify circuits. While specific colors vary by Ford model and year, common colors include:

- Red: Usually indicates a positive (+) power wire, often connected directly to the battery.

- Black: Typically represents a ground (-) wire, connected to the vehicle's chassis.

- Other Colors (Blue, Green, Yellow, etc.): Indicate specific circuits for signals or power to other components. Refer to the diagram's legend for specific color assignments.

How the 3-Pin Alternator System Works

The system operates as follows:

- Ignition Activation: When you turn the ignition key to the "on" position, the "I" (Ignition) wire receives power. This activates the voltage regulator within the alternator.

- Field Excitation: The voltage regulator sends a small amount of current to the alternator's field windings, creating a magnetic field.

- Stator Output: As the engine runs and the alternator pulley spins, the rotating magnetic field induces a voltage in the stator windings.

- Rectification: The AC voltage produced by the stator is converted to DC voltage by a set of diodes within the alternator (the rectifier bridge).

- Voltage Regulation: The voltage regulator monitors the battery voltage via the "A" (Voltage Sense) wire. If the battery voltage is low, the regulator increases the current to the field windings, increasing the alternator's output. If the battery voltage is high, the regulator reduces the current to the field windings, decreasing the alternator's output. This maintains a stable charging voltage.

- Stator Monitoring: The "S" (Stator) wire sends a signal to the voltage regulator indicating the load on the alternator. This helps the regulator optimize the charging process.

- Battery Charging: The regulated DC voltage from the alternator is then used to charge the battery and power the vehicle's electrical system.

Real-World Use and Basic Troubleshooting

Here are some common troubleshooting scenarios:

- Battery Not Charging: Check the "I" wire for power with the ignition on. Verify the alternator's ground connection. Use a multimeter to measure the voltage at the "A" wire with the engine running. It should be close to battery voltage. If the voltage is significantly lower than battery voltage (with the engine running), suspect a bad alternator or wiring issue. A faulty voltage regulator is also a common culprit.

- Overcharging: Check the voltage regulator (if external) or replace the alternator (if the regulator is internal). Overcharging can damage the battery and other electrical components.

- Warning Light On (or Dim): This can indicate a variety of issues, from a loose belt to a failing alternator. Use the wiring diagram to systematically check connections and voltages.

Basic Troubleshooting Steps:

- Visual Inspection: Check for damaged wiring, corroded connectors, and loose connections.

- Voltage Tests: Use a multimeter to measure voltage at various points in the circuit. Compare your measurements to the expected values.

- Continuity Tests: Use a multimeter to check for continuity in the wiring. This ensures that there are no breaks in the circuit.

- Load Testing: Use a load tester to check the alternator's output under load. This will help determine if the alternator is capable of delivering its rated current.

Safety Precautions

Working on electrical systems can be dangerous. Take the following precautions:

- Disconnect the Battery: Always disconnect the negative battery cable before working on any electrical components. This prevents accidental shorts and electrical shocks.

- Use Insulated Tools: Use insulated tools to prevent electrical shocks.

- Avoid Working in Wet Conditions: Water conducts electricity, increasing the risk of electrical shock.

- Identify Risky Components: The alternator's output is high-voltage. Be especially careful when working around the alternator and its wiring. Also, be extremely cautious when testing around the battery, as it can vent explosive gasses.

- Double-Check Connections: Ensure all connections are secure and properly insulated before reconnecting the battery. Incorrect wiring can cause serious damage to the electrical system.

Remember, the alternator is a high-output device. Careless handling can result in significant electrical damage or personal injury.

Having a reliable wiring diagram is crucial for successfully navigating the complexities of your Ford's electrical system. We have the file available for download, allowing you to have this essential resource at your fingertips.