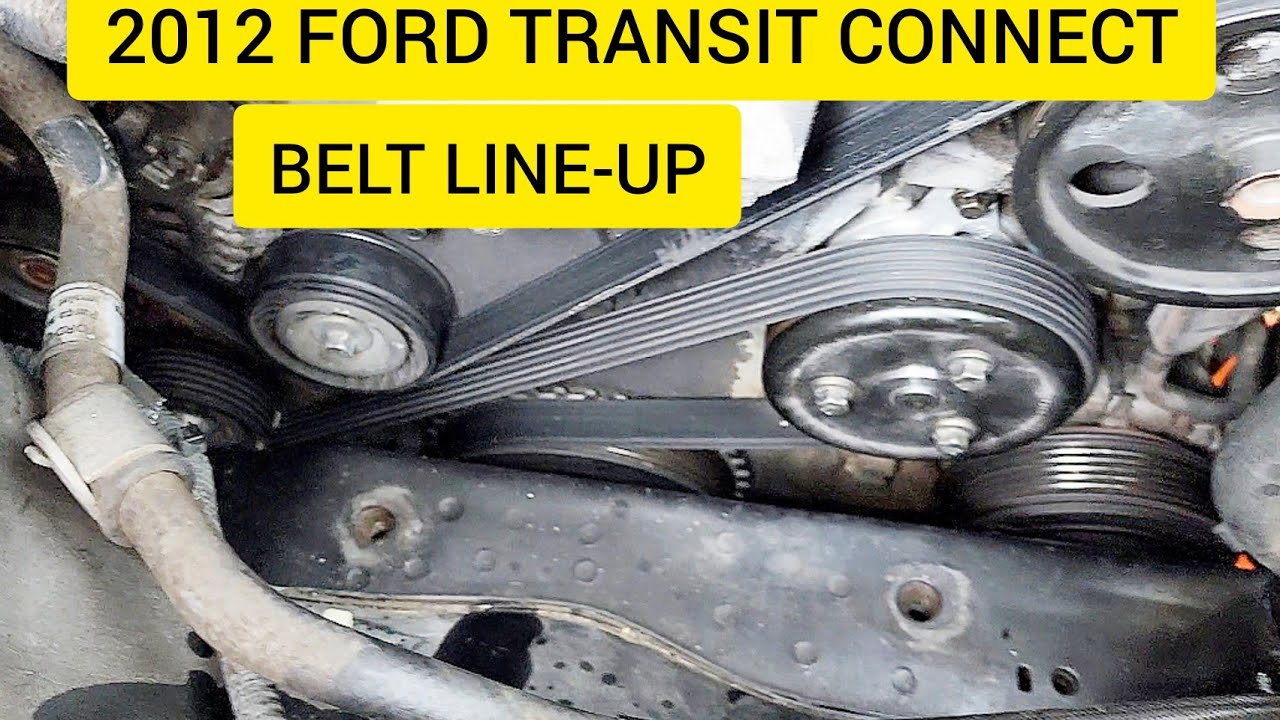

Ford Transit Serpentine Belt Diagram

So, you're tackling a serpentine belt replacement on your Ford Transit? Smart move. Knowing how the serpentine belt system works, and specifically understanding the diagram, is crucial for successful DIY repairs, upgrades, and even basic maintenance. This article will walk you through everything you need to know to interpret a Ford Transit serpentine belt diagram, from its purpose to real-world troubleshooting.

Why Bother with the Diagram?

The serpentine belt diagram is your roadmap for understanding the belt's routing. It's not just a pretty picture; it's a critical tool for several reasons:

- Repair and Replacement: When replacing a worn or broken belt, the diagram shows you the correct path to route the new belt. Incorrect routing can lead to component failure, reduced performance, or even catastrophic engine damage.

- Troubleshooting: A squealing belt? The diagram helps you identify which components are driven by the belt and could be the source of the noise (e.g., power steering pump, alternator).

- Preventative Maintenance: Familiarity with the system lets you spot potential problems early, like misaligned pulleys or failing tensioners.

- Understanding Engine Layout: For the mechanically inclined, the diagram reveals how the various accessories are driven by the engine, which enhances your overall understanding of the vehicle.

Key Specs and Main Parts

Before diving into the diagram itself, let's review the key components of a Ford Transit serpentine belt system. Keep in mind that specific configurations may vary slightly depending on the year, engine type (e.g., EcoBoost, diesel), and trim level of your Transit. However, the core components remain consistent.

- Serpentine Belt: The main component – a single, long belt that drives multiple engine accessories. It’s typically made of reinforced rubber.

- Crankshaft Pulley (Damper): Attached to the crankshaft, this pulley is the driving force of the entire system. Its rotation turns the serpentine belt.

- Alternator Pulley: Driven by the belt, the alternator generates electrical power for the vehicle.

- Power Steering Pump Pulley: Powers the hydraulic system for power steering.

- Air Conditioning Compressor Pulley: Engages to drive the A/C compressor when cooling is needed.

- Water Pump Pulley: Circulates coolant throughout the engine to regulate temperature.

- Idler Pulley(s): Smooth, bearing-equipped pulleys used to guide the belt around components and maintain proper tension.

- Tensioner Pulley: A spring-loaded pulley that automatically maintains the correct tension on the serpentine belt. This is crucial for proper operation and belt life. A worn tensioner can cause belt slippage and noise.

Decoding the Serpentine Belt Diagram

The diagram is a simplified representation of the belt's path around the pulleys. Understanding the symbols and conventions used is key to interpreting it correctly.

Lines and Routing

- Solid Lines: Represent the primary path of the belt. Follow these lines to see which pulleys the belt wraps around.

- Dotted Lines (Sometimes): May indicate the path of the belt on the backside of a pulley, or to show a specific orientation. They can also sometimes indicate optional configurations, though this is less common on Transit diagrams.

- Arrows: Indicate the direction of belt travel. It is very important to follow the arrows when routing the new belt.

- Pulley Overlap: Where lines overlap, this indicates that the belt is wrapping around the pulley in that direction.

Pulley Icons

- Circles: The fundamental shape for representing pulleys. The size might vary slightly to differentiate between pulleys but isn’t necessarily representative of their actual physical size.

- Labels: Each pulley is typically labeled with a letter abbreviation (e.g., ALT for Alternator, P/S for Power Steering, CMP for Compressor, IDL for idler, TEN for Tensioner). These abbreviations should be clearly defined in the diagram key.

- Grooves/No Grooves: The presence or absence of grooves on the pulley icon indicates whether the smooth or grooved side of the belt should contact the pulley. Grooved pulleys typically drive accessories, while smooth pulleys are often idlers.

Color Coding (Less Common, but Possible)

Some diagrams might use color coding to highlight specific sections of the belt path or differentiate between components. If present, a legend should explain the meaning of each color.

How It Works: The Serpentine Belt System in Action

The crankshaft pulley, driven by the engine's rotation, provides the power to turn the serpentine belt. As the belt rotates, it spins the pulleys of the various accessories. The tensioner pulley maintains the correct belt tension, ensuring that the belt doesn't slip and that each accessory receives the necessary power. Without proper tension, the accessories won't function correctly (e.g., the alternator might not charge the battery adequately, the power steering might feel heavy, or the A/C might blow warm air).

The serpentine belt system is a critical part of your vehicle, ensuring that all your auxiliary systems operate correctly and provide comfort and safety as you drive.

Real-World Use: Basic Troubleshooting Tips

Here are a few common serpentine belt issues and how the diagram can help with troubleshooting:

- Squealing Belt: This often indicates a loose belt, a worn belt, or a failing pulley bearing. Use the diagram to check the tensioner's position and look for signs of wear on the belt (cracks, glazing). Try spraying a very small amount of belt dressing on the belt (only do this as a diagnostic step). If the noise stops briefly, it confirms belt slippage. Inspect pulleys for wobbling, which could indicate a failing bearing.

- Belt Slippage: Manifests as a lack of power steering, poor A/C performance, or a dimming of headlights (due to low alternator output). Check the belt tension and look for debris on the pulleys.

- Belt Damage/Wear: Inspect the belt regularly for cracks, fraying, or missing chunks. Replace the belt if you find significant damage. Use the diagram to ensure you are buying the correct length and type of belt for your model.

- Component Failure: If an accessory (e.g., alternator, power steering pump) fails, it can sometimes damage the serpentine belt. Use the diagram to confirm that the accessory is driven by the belt and to check for any signs of damage caused by the failure.

Safety Considerations

Working on the serpentine belt system involves inherent risks. Never work on the system with the engine running. The rotating components can cause serious injury. Disconnect the negative battery terminal before starting any work to prevent accidental starting. Be especially cautious around the tensioner pulley, as it's under significant spring tension. Use the correct tools to release the tension before removing the belt. Also, be aware of hot engine components if the vehicle has been running recently.

The tensioner can be extremely dangerous. The spring is very powerful, so make sure you are using the correct tools to relieve the tension. Do not attempt to release the tensioner with improvised tools; this could lead to injury.

Always wear safety glasses when working under the hood. Keep hands and fingers clear of moving parts. If you're unsure about any step, consult a qualified mechanic.

Get the Diagram!

We have a downloadable Ford Transit serpentine belt diagram available for your use. Having a clear, readily accessible diagram is invaluable for any maintenance or repair work you plan to undertake. This resource can save you time, prevent mistakes, and ultimately, help you keep your Transit running smoothly.

Remember to always double-check the diagram against your specific vehicle's configuration, as slight variations can occur.