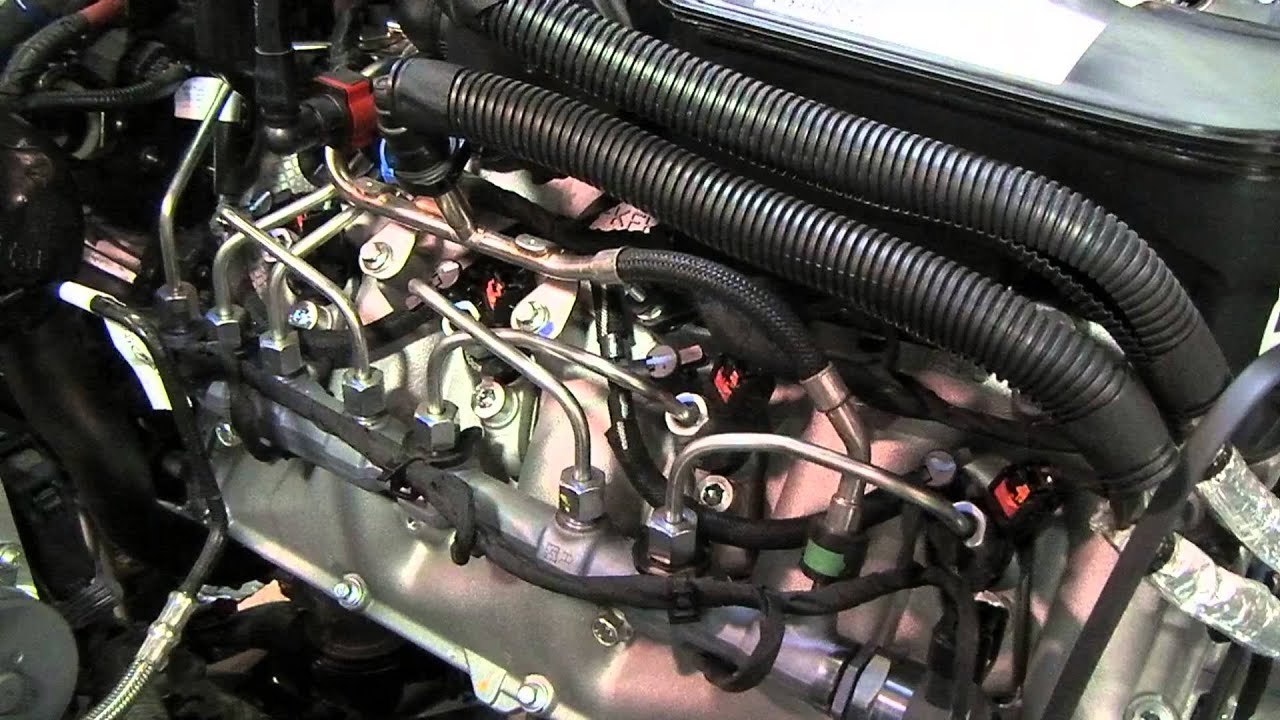

High Pressure 6.7 Powerstroke Fuel System Diagram

Understanding the high-pressure fuel system of your 6.7 Powerstroke diesel is crucial for effective diagnostics, repairs, and even performance modifications. This detailed guide will walk you through the system's diagram, explaining its components, operation, and potential troubleshooting areas. We’re assuming you have some familiarity with automotive mechanics and diesel engines. This information is not a substitute for professional guidance, but it will equip you with a strong foundation to tackle fuel system related issues.

Why Bother with a Fuel System Diagram?

A fuel system diagram isn't just a pretty picture; it's a roadmap to understanding how your engine gets its lifeblood. Knowing this diagram will help you:

- Diagnose Fuel System Problems: Pinpoint the source of issues like hard starting, low power, or excessive smoke.

- Perform Repairs: Identify components needing replacement and understand their relationship to the rest of the system.

- Plan Modifications: Upgrade fuel system components for increased performance, knowing what's compatible and how it will affect overall system operation.

- Improve Your Knowledge: Gain a deeper understanding of how your 6.7 Powerstroke engine works.

We understand the value of having access to a quality high-resolution image of the fuel system diagram. We have a detailed fuel system diagram available for download; you'll find the link at the end of this article.

Key Specs and Main Parts of the 6.7 Powerstroke Fuel System

The 6.7 Powerstroke utilizes a common rail, high-pressure fuel injection system. This means fuel is pressurized in a common rail and then injected into each cylinder via electronically controlled injectors. Here are the main components:

- Fuel Tank: Stores the diesel fuel.

- Low-Pressure Fuel Pump (Lift Pump): Located either in the fuel tank or along the frame rail, it draws fuel from the tank and supplies it to the high-pressure fuel pump. Early models sometimes had issues with the lift pump, so monitoring its performance is essential.

- Fuel Filter(s): Removes contaminants from the fuel, protecting the injectors and high-pressure pump. The 6.7 Powerstroke typically has two fuel filters - a primary and secondary.

- High-Pressure Fuel Pump (HPFP) - Bosch CP4.2: This is a critical component. It’s responsible for generating the extremely high fuel pressure required for injection (typically 5,000-29,000 PSI or 350-2000 bar). The CP4.2 pump has been the subject of scrutiny due to its susceptibility to failure when contaminated fuel enters the system.

- Fuel Rail (Common Rail): A high-pressure reservoir that stores fuel at the required pressure. It distributes fuel evenly to all injectors.

- Fuel Injectors: Electronically controlled nozzles that spray fuel into the combustion chamber at precise times and amounts. They are sophisticated devices that are finely tuned for optimal performance and emissions.

- Fuel Pressure Regulator/Relief Valve: Maintains consistent fuel pressure in the rail. It releases excess pressure to prevent damage to the system.

- Fuel Return Line: Returns excess fuel from the injectors and pressure regulator back to the fuel tank. This helps cool the fuel and prevent vapor lock.

- Fuel Temperature Sensor: Monitors fuel temperature, providing data to the engine control module (ECM) for optimized fuel delivery.

- Engine Control Module (ECM): The brain of the engine, controlling fuel injection timing, duration, and pressure based on various sensor inputs.

Understanding the Fuel System Diagram Symbols

A fuel system diagram uses standardized symbols to represent different components and lines. Here are some common symbols you'll encounter:

- Solid Lines: Represent fuel lines carrying fuel under pressure. Line thickness may indicate the diameter of the line.

- Dashed Lines: Often represent electrical wiring or vacuum lines.

- Arrows: Indicate the direction of fuel flow.

- Rectangles: Typically represent components like fuel filters, sensors, or the ECM.

- Circles: Can represent various components like pumps or regulators.

- Color Coding: Some diagrams use color coding to differentiate between supply lines, return lines, and vacuum lines. Always refer to the diagram's legend for specific color interpretations.

How the 6.7 Powerstroke Fuel System Works

The system operates in a sequential manner:

- The lift pump draws fuel from the fuel tank.

- Fuel passes through the primary and secondary fuel filters to remove contaminants.

- The HPFP (CP4.2) dramatically increases the fuel pressure.

- High-pressure fuel is stored in the common rail.

- The ECM signals the fuel injectors to open and spray fuel into the cylinders at precisely timed intervals.

- Excess fuel is returned to the fuel tank via the fuel return line.

- The fuel pressure regulator maintains consistent rail pressure.

The ECM monitors numerous sensors (fuel pressure, fuel temperature, engine speed, etc.) to adjust fuel delivery for optimal performance, emissions, and fuel economy. This closed-loop feedback system allows for precise control over the combustion process.

Real-World Use: Basic Troubleshooting Tips

Here are some basic troubleshooting tips related to the fuel system:

- Hard Starting: Could be caused by a faulty lift pump, clogged fuel filter, air in the fuel system, or a failing HPFP. Check fuel pressure at the rail using a diagnostic tool.

- Low Power: Possible causes include a clogged fuel filter, failing lift pump, a failing HPFP, or malfunctioning injectors. Inspect fuel filter for debris, check fuel pressure, and consider an injector balance test.

- Excessive Smoke: Black smoke can indicate over-fueling due to faulty injectors or incorrect ECM programming. White smoke can indicate unburnt fuel due to low compression or injector problems. Blue smoke suggests burning oil.

- Fuel Leaks: Inspect all fuel lines, fittings, and components for leaks. Diesel fuel leaks are a fire hazard.

- Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to retrieve DTCs related to the fuel system. Research the codes and follow the diagnostic procedures outlined in the service manual.

Always start with the simplest and most accessible checks first, such as inspecting the fuel filter and checking for fuel leaks. A diagnostic scan tool is invaluable for reading fuel pressure and injector parameters.

Safety Considerations

Working on a high-pressure fuel system can be dangerous. Here are some critical safety precautions:

- Depressurize the Fuel System: Before disconnecting any fuel lines or components, always depressurize the fuel system to prevent fuel from spraying out under high pressure. Refer to the service manual for the proper depressurization procedure.

- Wear Safety Glasses: Protect your eyes from fuel spray.

- Work in a Well-Ventilated Area: Diesel fumes are harmful.

- Avoid Sparks and Open Flames: Diesel fuel is flammable.

- Use Appropriate Tools: Use the correct tools for the job to avoid damaging components.

- HPFP (CP4.2) Precautions: Be extremely careful when working on or around the HPFP. A catastrophic HPFP failure can send metal debris throughout the fuel system, requiring replacement of the pump, injectors, fuel rails, and fuel lines. Consider using fuel additives designed to lubricate the HPFP and prevent wear.

Remember, if you are not comfortable working on the fuel system, it's best to consult a qualified diesel mechanic.

Having a diagram is important, and we want to make it easier for you. You can download a detailed diagram of the 6.7 Powerstroke fuel system [Insert Download Link Here].