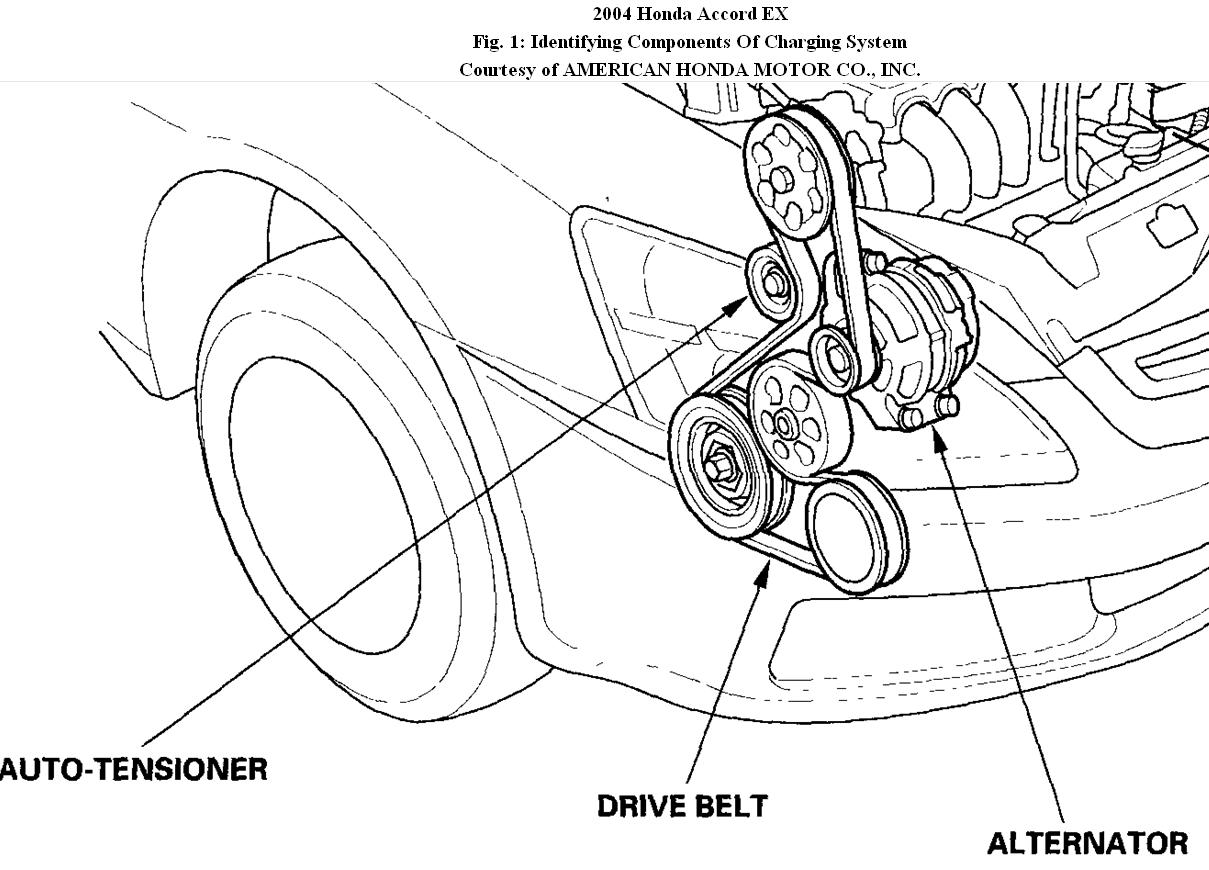

Honda Accord Serpentine Belt Diagram

The serpentine belt in your Honda Accord is a critical component responsible for powering several vital accessories. Understanding its routing and maintenance is crucial for any DIY mechanic or experienced car owner. This article provides a detailed breakdown of the Honda Accord serpentine belt diagram, covering its purpose, key components, functionality, and troubleshooting.

Purpose of the Serpentine Belt Diagram

The serpentine belt diagram is your roadmap to properly installing and maintaining the serpentine belt. It serves several key purposes:

- Proper Installation: It illustrates the correct routing of the belt around all the pulleys, ensuring optimal performance and preventing premature wear. Incorrect routing can cause the belt to slip, fail, or damage the accessories it drives.

- Troubleshooting: When diagnosing issues like squealing noises or failing accessories, the diagram helps you identify potential problems, such as a misaligned pulley or a worn-out tensioner.

- Replacement Guide: It acts as a visual guide during belt replacement, preventing errors and ensuring the new belt is installed correctly.

- Learning & Education: For car enthusiasts and DIYers, understanding the serpentine belt diagram helps grasp the accessory drive system's overall functionality.

In essence, the diagram is an indispensable tool for anyone working on their Honda Accord's accessory drive system. We have a high-resolution serpentine belt diagram available for download, which you can use for detailed reference.

Key Specs and Main Parts

The serpentine belt system comprises several key components, each with a specific role. Understanding these parts is vital for interpreting the diagram correctly.

Main Components:

- Serpentine Belt: The endless belt made of reinforced rubber that transmits power from the crankshaft to the accessories. The length and width specifications are crucial for compatibility (typically denoted by part number, e.g., 7PK1770, where 7 refers to number of ribs and 1770 is the length in mm).

- Crankshaft Pulley (Crank Pulley): Located at the end of the crankshaft, this pulley receives power directly from the engine. It is the *driving* pulley of the serpentine belt system.

- Alternator Pulley: Drives the alternator, which charges the battery and powers the electrical system.

- Power Steering Pump Pulley: Drives the power steering pump, which provides hydraulic assistance for steering.

- Air Conditioning Compressor Pulley (A/C Compressor Pulley): Drives the A/C compressor, which circulates refrigerant to cool the cabin.

- Idler Pulley(s): Smooth, bearing-mounted pulleys used to guide the belt and increase its contact area with other pulleys. They don't drive any accessories.

- Tensioner Pulley: This spring-loaded pulley maintains the correct tension on the serpentine belt. A worn or failing tensioner can cause belt slippage and noise.

Key Specs:

- Belt Length: Specified in millimeters or inches, this is critical for proper fit. Using the wrong length can lead to insufficient tension or inability to install the belt.

- Belt Width: The width must match the grooves on the pulleys.

- Rib Count: The number of ribs on the belt must match the corresponding grooves on the pulleys. A mismatch can cause the belt to ride improperly and fail prematurely.

- Torque Specifications: The tensioner pulley usually has a specified torque setting for tightening after belt replacement. Consult your Accord's repair manual.

Symbols and Diagram Explanation

Serpentine belt diagrams use various symbols to represent different components and aspects of the belt routing.

- Solid Lines: Indicate the path of the outer surface of the belt. The belt runs along this side.

- Dashed Lines: Usually represent the inner surface of the belt, indicating where the belt wraps around the pulley.

- Arrows: Show the direction of belt rotation. Understanding the rotation is crucial for ensuring correct installation.

- Pulleys: Represented by circles. The diagram often labels each pulley with its corresponding component (e.g., ALT for Alternator, P/S for Power Steering).

- Tensioner: Often depicted with a symbol showing a spring or adjustable mechanism.

- Idler Pulleys: Usually marked with "IDLER" or simply depicted as a smooth pulley.

Colors are not standardized across all diagrams, but some common conventions exist. For example, some diagrams may use different colors to distinguish between the belt's path on the front and back sides of the engine.

How It Works

The serpentine belt system operates on a simple principle: power transfer through friction. The crankshaft pulley, driven by the engine's rotation, turns the serpentine belt. The belt, in turn, wraps around and drives the pulleys of various accessories, such as the alternator, power steering pump, and A/C compressor.

The tensioner pulley plays a crucial role in maintaining the correct belt tension. Too little tension can cause the belt to slip, leading to reduced accessory performance and potential overheating. Too much tension can overload the bearings of the accessory pulleys, shortening their lifespan and potentially damaging the belt itself.

The arrangement of pulleys in the system is carefully designed to maximize belt contact area and ensure efficient power transfer. Idler pulleys help guide the belt and increase its wrap angle around the other pulleys. The serpentine design allows a single belt to drive multiple accessories, simplifying the engine layout and reducing maintenance complexity.

Real-World Use – Basic Troubleshooting Tips

Common problems associated with the serpentine belt system include:

- Squealing Noise: Often caused by a slipping belt due to low tension, a worn belt, or a contaminated pulley. Inspect the belt for cracks, glazing, or wear. Check the tensioner's operation.

- Accessory Failure: If an accessory stops working, the belt may be broken or slipping on that particular pulley. A broken belt will immediately render all accessories nonfunctional, while slipping might only affect one or two.

- Cracked or Frayed Belt: Indicates normal wear and tear or misalignment. Replace the belt immediately.

- Tensioner Problems: A noisy or wobbly tensioner can cause belt slippage and damage. Replace the tensioner if it is malfunctioning.

When troubleshooting, use the serpentine belt diagram to:

- Verify the belt routing. Ensure it matches the diagram.

- Identify the pulleys involved in the suspected issue.

- Inspect the belt and pulleys for wear, damage, or contamination.

- Check the tensioner's operation. It should move smoothly and maintain adequate tension.

Safety Considerations

Working on the serpentine belt system can be hazardous due to the proximity of moving parts and the potential for electrical shock.

- Disconnect the Battery: Before starting any work, disconnect the negative battery terminal to prevent accidental electrical shorts.

- Hot Engine: Never work on the serpentine belt system when the engine is hot. Allow it to cool down completely.

- Moving Parts: Keep hands, tools, and clothing away from the belt and pulleys when the engine is running.

- Tensioner Spring: The tensioner spring is under considerable force. Use appropriate tools to relieve the tension when removing or installing the belt. A slip could lead to serious injury.

- Alternator: Be cautious when working near the alternator, as it contains high-voltage components even after the engine is turned off. Wait for a period for it to safely discharge.

Proper safety precautions are essential to prevent injuries and ensure a successful repair.

Remember, we have a downloadable high-resolution serpentine belt diagram for your Honda Accord. This will be a valuable asset in performing any maintenance or repairs on your vehicle's accessory drive system. Good luck!