Jeep Grand Cherokee Wiring Schematic

The Jeep Grand Cherokee is a rugged and reliable vehicle, but like all modern cars, its complex electrical system can be daunting to diagnose and repair. Understanding the wiring schematic for your Grand Cherokee is crucial for a range of tasks, from simple accessory installations to complex troubleshooting. This article will provide a comprehensive guide to interpreting these schematics, empowering you to tackle your Jeep's electrical challenges with confidence.

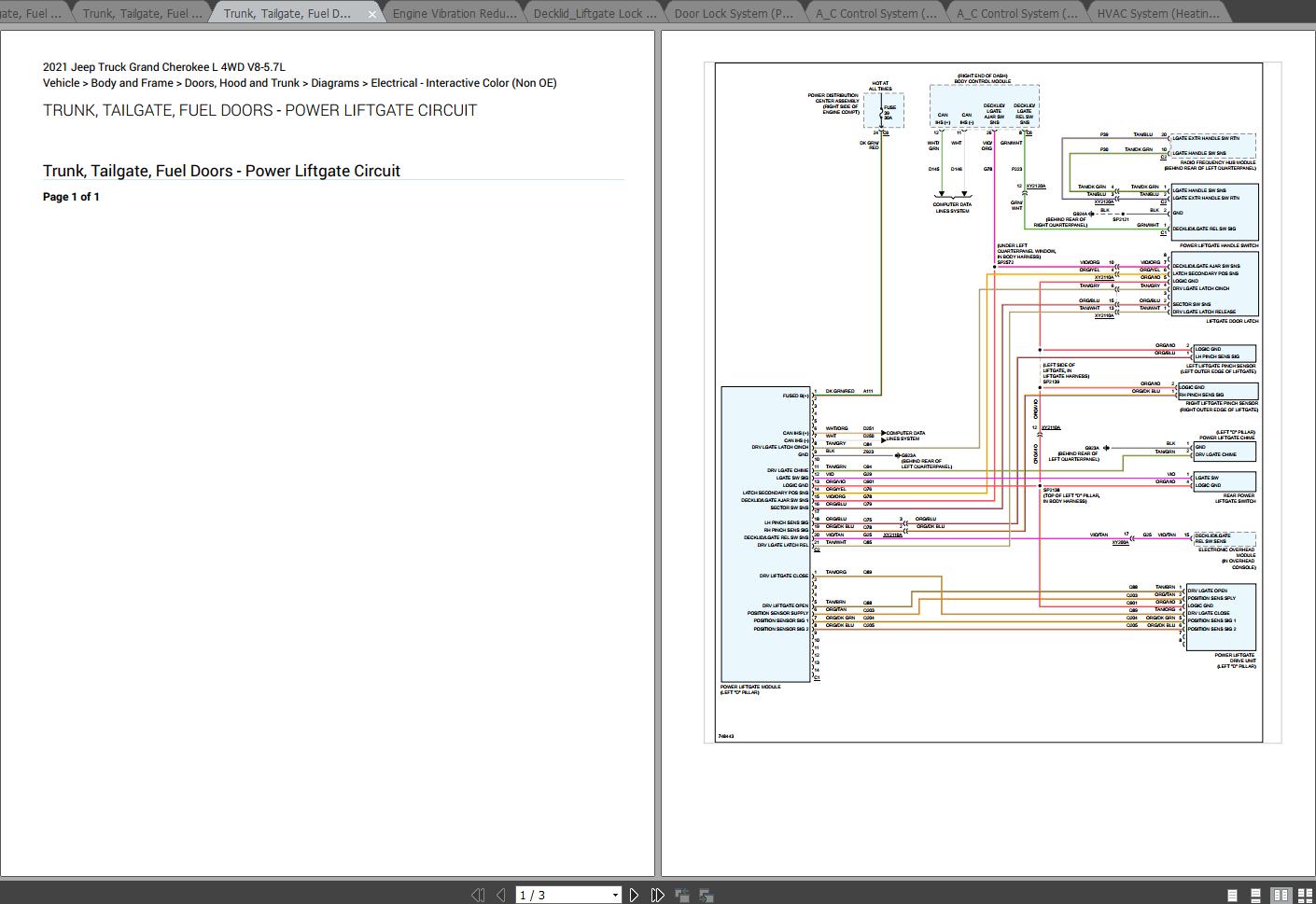

Purpose of a Wiring Schematic

A wiring schematic, also known as a wiring diagram, is a visual representation of the electrical circuits in your Jeep Grand Cherokee. It shows how all the electrical components are connected, including wires, connectors, fuses, relays, and electronic control modules (ECMs). It’s not a physical layout of the wires, but rather a logical map of the electrical system.

Why is understanding this important? Consider these scenarios:

- Troubleshooting Electrical Issues: If your headlights aren't working, or the power windows refuse to roll down, the schematic can help you trace the circuit and pinpoint the faulty component.

- Installing Aftermarket Accessories: Adding a new sound system, off-road lights, or a trailer brake controller requires you to tap into the existing wiring. The schematic will show you where to safely connect these accessories.

- Performing Repairs: Replacing a damaged wire harness or repairing a faulty connector is much easier with a clear understanding of the wiring layout.

- Learning about Your Vehicle: Simply understanding the electrical system can deepen your knowledge of your Grand Cherokee and how it operates.

Key Specs and Main Parts of a Jeep Grand Cherokee Wiring Diagram

Jeep Grand Cherokee wiring schematics are often divided into sections based on specific systems, such as:

- Powertrain: Engine control, transmission, and related sensors.

- Body Electrical: Lights, wipers, power windows, door locks, and interior accessories.

- Chassis Electrical: Anti-lock brakes (ABS), traction control, and suspension systems.

- Instrument Panel: Gauges, warning lights, and infotainment system.

A typical schematic will include the following key components:

- Wires: Represented by lines, often with different colors and gauges.

- Connectors: Show where wires are joined together, often with specific connector identifiers.

- Fuses: Protective devices that break the circuit if excessive current flows.

- Relays: Electrically operated switches that control high-current circuits.

- Switches: Manually operated devices that open or close circuits.

- Sensors: Devices that measure various parameters, such as temperature, pressure, and speed.

- Actuators: Devices that perform a mechanical action, such as motors and solenoids.

- Electronic Control Modules (ECMs): Computerized units that control various vehicle systems. The Powertrain Control Module (PCM) is a major player, controlling the engine and transmission.

- Grounds: Connection points to the vehicle's chassis, providing a return path for current.

Understanding Wiring Schematic Symbols

Decoding the symbols on a wiring schematic is essential for proper interpretation. Here's a breakdown of common symbols:

- Lines: Solid lines represent wires. Thicker lines often indicate wires that carry more current. Dashed lines may represent shielded cables or network communication lines (like CAN bus).

- Colors: Each wire is identified by a color code (e.g., RD for Red, BLK for Black, YEL for Yellow). Some wires may have a stripe of a different color (e.g., GRN/WHT for Green with a White stripe).

- Connectors: Represented by various shapes, often rectangles or circles with pins inside. The schematic will usually include a connector identifier (e.g., C101) that can be used to locate the physical connector in the vehicle.

- Fuses: Represented by a squiggly line inside a rectangle. The amperage rating of the fuse is usually indicated next to the symbol.

- Relays: Represented by a coil symbol (the relay's electromagnet) and a switch symbol (the contacts that the relay controls).

- Switches: Represented by a line that can be opened or closed. Different types of switches (e.g., single-pole single-throw (SPST), single-pole double-throw (SPDT)) have different symbols.

- Grounds: Represented by a symbol that looks like a series of downward-pointing arrows.

Beyond these basic symbols, you'll encounter specific symbols for different types of sensors, actuators, and other components. Consult the legend or key on the schematic for a complete list of symbols.

How It Works: Tracing a Circuit

The key to using a wiring schematic is to learn how to trace a circuit. Here's a simplified example:

Let's say you're troubleshooting a malfunctioning headlight. Start by identifying the headlight circuit on the schematic. You'll see the power source (battery), the fuse, the switch, the wiring, the headlight bulb, and the ground connection.

- Start at the Power Source: Follow the wire from the battery, noting its color and gauge.

- Check the Fuse: Verify that the fuse is intact. If it's blown, replace it and see if it blows again. A repeatedly blowing fuse indicates a short circuit.

- Follow the Wiring: Trace the wire through the switch and to the headlight bulb. Check for any breaks, shorts, or corrosion.

- Check the Ground: Ensure that the headlight bulb has a good ground connection. Clean any corroded ground points.

By systematically tracing the circuit, you can isolate the faulty component.

Real-World Use: Basic Troubleshooting Tips

- Start with the Basics: Before diving into the schematic, check the obvious things: fuses, bulbs, and connectors.

- Use a Multimeter: A multimeter is an essential tool for electrical troubleshooting. Use it to measure voltage, current, and resistance.

- Look for Patterns: If multiple components are malfunctioning, it's likely that the problem is with a common power supply or ground.

- Isolate the Problem: Disconnect components one at a time to isolate the source of the problem.

- Consult Technical Service Bulletins (TSBs): TSBs are issued by manufacturers to address common problems. They may provide valuable insights into the issue you're facing.

Safety Precautions

Working with automotive electrical systems can be dangerous. Take the following precautions:

- Disconnect the Battery: Before working on any electrical circuit, disconnect the negative battery cable to prevent short circuits and electrical shocks.

- Use Proper Tools: Use insulated tools designed for automotive electrical work.

- Avoid Working in Wet Conditions: Water can conduct electricity and increase the risk of shock.

- Be Careful with Airbags: Airbags are explosive devices. Follow the manufacturer's instructions carefully when working near airbags. Never probe airbag connectors with a multimeter, as this could trigger the airbag.

- Be Aware of High-Voltage Components: Hybrid and electric vehicles have high-voltage components that can be lethal. Only qualified technicians should work on these components. Capacitors can hold a charge long after the battery is disconnected.

- Consult a Professional: If you're not comfortable working on the electrical system, consult a qualified mechanic.

Always remember to disconnect the negative battery terminal before undertaking any electrical work on your vehicle. This simple step can prevent serious injury and damage to your Jeep.

Accessing the Wiring Diagram

High-quality wiring diagrams are essential for accurate troubleshooting. Generic diagrams found online may not be specific to your Jeep's model year and trim level, leading to incorrect diagnoses and potential damage.

We have a comprehensive Jeep Grand Cherokee wiring diagram file available for download. This detailed resource can significantly aid in your diagnostic and repair efforts.

By understanding and properly utilizing a wiring schematic, you can confidently tackle a wide range of electrical issues on your Jeep Grand Cherokee, saving you time and money while deepening your understanding of your vehicle.