John Deere Voltage Regulator Wiring Diagram

Decoding the John Deere Voltage Regulator Wiring Diagram: A DIYer's Guide

If you're a hands-on mechanic, a dedicated modder, or simply a John Deere owner who likes to keep things running smoothly, understanding the voltage regulator wiring diagram for your machine is absolutely essential. It's your roadmap for diagnosing electrical problems, performing repairs, and even upgrading your system. This isn't just a piece of paper; it's the key to unlocking your John Deere's electrical secrets.

Purpose: This article aims to provide a comprehensive understanding of John Deere voltage regulator wiring diagrams, enabling you to confidently troubleshoot electrical issues, perform necessary repairs, and even implement system upgrades.

Why This Diagram Matters

Imagine your tractor's battery isn't charging, or your lights are flickering erratically. Without a wiring diagram, you're essentially groping in the dark. The diagram allows you to:

- Accurately diagnose problems: Pinpoint the exact location of faults in the charging system.

- Perform repairs effectively: Ensures you're connecting wires correctly and replacing components properly.

- Understand the system: Gains insight into how the voltage regulator interacts with the rest of the electrical system.

- Facilitate modifications: Allows for the safe and informed addition of aftermarket accessories.

Key Specs and Main Parts

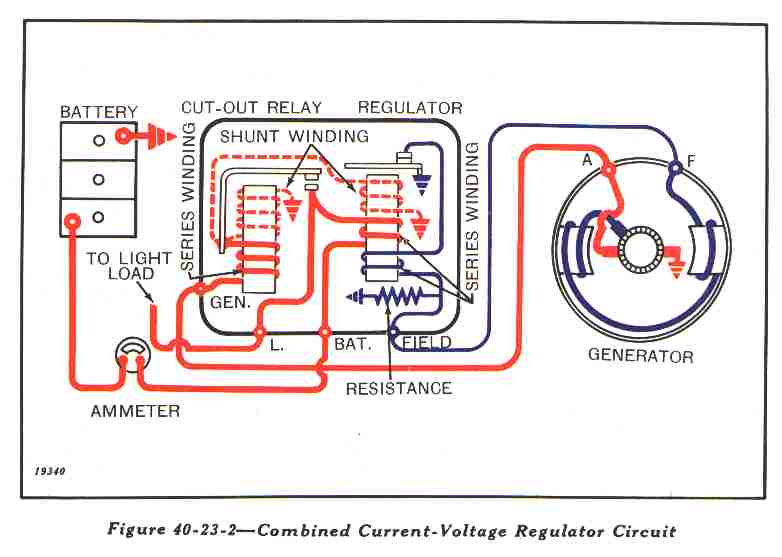

Before diving into the diagram itself, let's review the key components of a typical John Deere charging system and their relationship to the voltage regulator. Remember that specific configurations vary between John Deere models, so always refer to the correct diagram for your machine.

- Alternator/Stator: This is the electricity generator, usually driven by the engine. It produces AC (Alternating Current) voltage.

- Rectifier: Converts the AC voltage from the alternator/stator to DC (Direct Current) voltage, which is required by the battery and the rest of the electrical system. Often integrated into the voltage regulator.

- Voltage Regulator: This is the brain of the system. It maintains a stable DC voltage output (typically around 13.5-14.5 volts) to charge the battery and power the electrical loads. It prevents overcharging, which can damage the battery.

- Battery: Provides the initial power to start the engine and acts as a reservoir of electrical energy.

- Ignition Switch: Controls the flow of power to the starting and charging systems.

- Fuses/Circuit Breakers: Protect the electrical system from overcurrents and short circuits.

- Wiring Harness: The network of wires that connects all the components.

Decoding the Diagram: Symbols and Conventions

Understanding the symbols used in the wiring diagram is crucial for interpreting the information it conveys.

Lines:

- Solid Lines: Represent wires carrying electrical current. The thickness of the line *sometimes* indicates the wire gauge (thicker lines often mean larger gauge wires carrying more current).

- Dashed Lines: May indicate connections to ground (chassis ground), signal wires, or wires that are shielded.

- Lines with Arrows: Show the direction of current flow (conventional current flow: positive to negative).

Colors:

Wire colors are standardized, but variations exist, especially in older models. A key will be provided with the diagram, indicating what each color represents. Common colors include:

- Red: Typically indicates power from the battery.

- Black: Usually represents ground (negative connection).

- Yellow: Often used for lighting circuits.

- Green: Common for signal wires or sensor connections.

- Blue: Can be used for various circuits, depending on the manufacturer.

Icons:

Icons represent electrical components. Some common icons include:

- Battery Symbol: A series of alternating long and short lines.

- Ground Symbol: Often a series of descending lines connected to a single point, or a triangle.

- Fuse Symbol: A squiggly line inside a rectangle.

- Switch Symbol: A line that can be opened or closed to connect or disconnect a circuit.

- Resistor Symbol: A zig-zag line.

- Diode Symbol: A triangle pointing to a line.

- Alternator/Stator Symbol: A circle with three wavy lines inside.

- Voltage Regulator Symbol: Usually a rectangle or square with input and output terminals labeled.

How It Works: The Charging System in Action

The charging system works in a closed loop. The engine drives the alternator/stator, which produces AC voltage. The rectifier converts this AC voltage to DC voltage. The voltage regulator then steps in to control this DC voltage. It senses the battery's voltage. If the battery voltage is low, the regulator allows more current to flow from the alternator/stator to the battery, charging it. If the battery is fully charged, the regulator reduces or stops the current flow to prevent overcharging.

The voltage regulator achieves this control through various methods, depending on the type of regulator. Older mechanical regulators used points and coils to switch circuits on and off. Modern solid-state regulators use transistors or integrated circuits to achieve the same result with greater efficiency and reliability.

Real-World Use: Basic Troubleshooting Tips

Here are a few common problems and how the wiring diagram can help you diagnose them:

- Battery Not Charging:

- Check the wiring diagram to trace the circuit from the alternator/stator to the battery.

- Use a multimeter to check for voltage at various points in the circuit.

- Look for broken wires, corroded connections, or blown fuses.

- Overcharging:

- This is often a sign of a faulty voltage regulator.

- Use the diagram to identify the regulator's connections and check its output voltage.

- Replace the regulator if it's consistently outputting a voltage higher than the specified range (typically 13.5-14.5 volts).

- Flickering Lights:

- This can be caused by a loose connection, a faulty ground, or a problem with the voltage regulator.

- Use the diagram to trace the lighting circuit and check for loose or corroded connections.

- Verify the voltage regulator's output is stable.

Safety First!

Working with electrical systems can be dangerous. Always take the following precautions:

- Disconnect the Battery: Before working on any electrical component, disconnect the negative (-) battery terminal to prevent short circuits.

- Use Insulated Tools: Use tools with insulated handles to prevent electric shock.

- Be Careful Around the Alternator/Stator: The alternator/stator can generate high voltages, especially when the engine is running. Avoid touching the terminals when the engine is on.

- Work in a Well-Ventilated Area: Batteries can produce explosive gases. Ensure adequate ventilation when working around batteries.

Important: The voltage regulator and surrounding circuits can contain capacitors that store a charge even after the battery is disconnected. Exercise caution when handling these components. Allow sufficient time for capacitors to discharge, or use a suitable discharge tool.

Remember, safety is paramount. If you're unsure about any aspect of the repair, consult a qualified mechanic.

Armed with this knowledge and the correct wiring diagram, you'll be well-equipped to tackle electrical issues on your John Deere machine. It's empowering to understand how your equipment functions, and this guide, along with your diagram, will help you achieve that understanding.

We have a downloadable copy of a sample John Deere voltage regulator wiring diagram available. Contact us, and we can provide you with the file to further assist you in your diagnostic and repair work.