Mcculloch Chainsaw Fuel Line Diagram

So, you’re tackling a fuel line issue on your McCulloch chainsaw? Excellent! Understanding the fuel system is crucial for diagnosing problems, performing repairs, and even optimizing performance. This article breaks down the McCulloch chainsaw fuel line diagram, equipping you with the knowledge to confidently troubleshoot and maintain this vital component. We're talking about diagrams for older models here; while newer saws share principles, details might vary. Remember that safety is paramount when dealing with fuel and potentially sharp objects like chainsaw components.

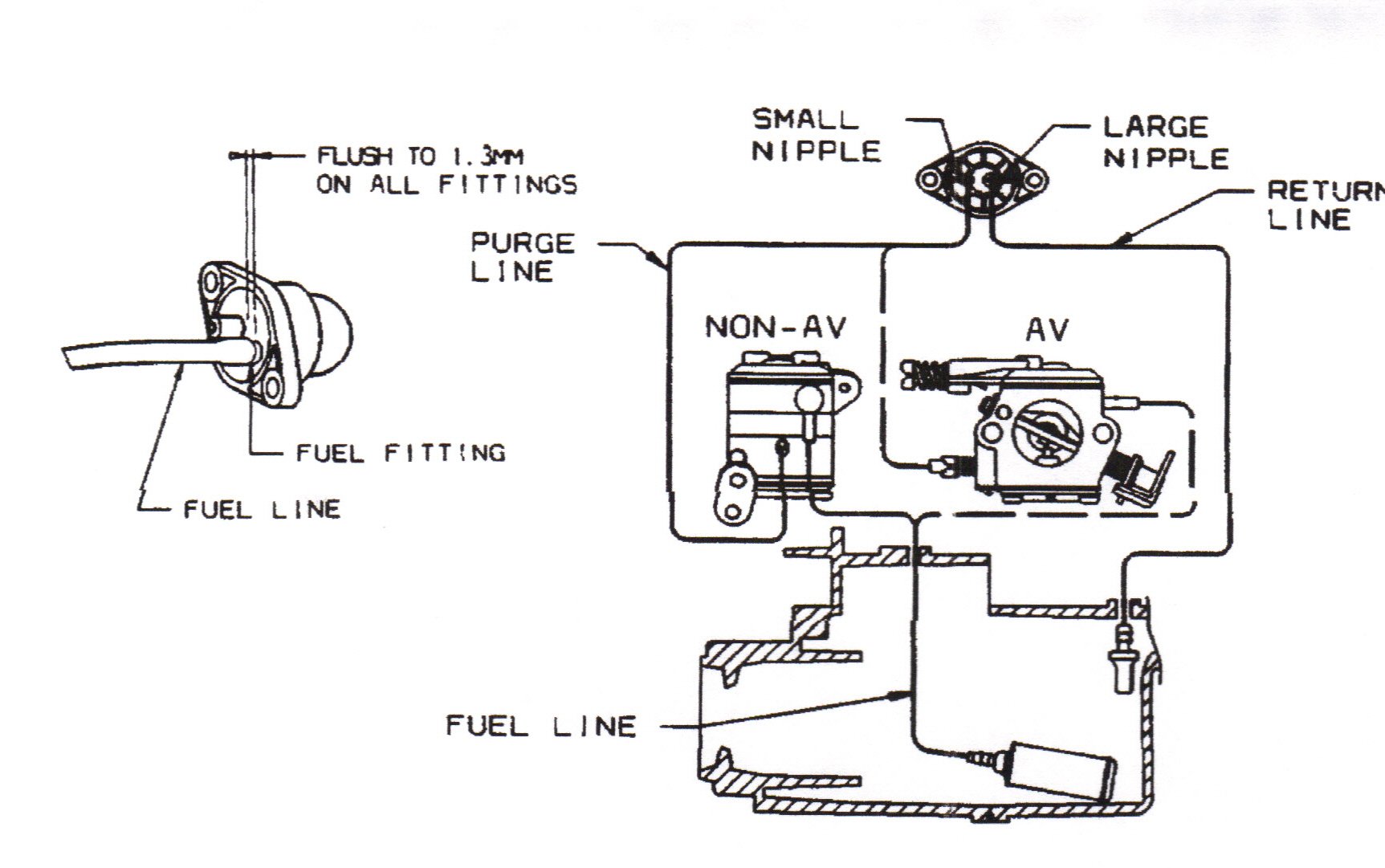

Purpose of the Fuel Line Diagram

Why bother with a diagram? Simply put, it's your roadmap to the fuel system. A fuel line diagram helps you:

* Identify Components: It shows you where each part is located and what it's called (fuel tank, filter, lines, carburetor, etc.). * Trace the Flow: It illustrates the path the fuel takes from the tank to the engine. This is critical for understanding how the system works and where blockages might occur. * Troubleshoot Problems: By following the diagram, you can systematically check each component for leaks, clogs, or damage. * Perform Repairs: When replacing fuel lines or other components, the diagram ensures you reconnect everything correctly. * Learn About the System: It provides a visual representation that makes understanding the fuel system much easier, even if you're relatively new to small engine repair. * Modification/Upgrades: If you are going to modify your chainsaw, understanding the current fuel system will help you do this safely and effectively.Key Specs and Main Parts

Let's delve into the core components typically found in a McCulloch chainsaw fuel system:

* Fuel Tank: This is where the fuel (usually a mix of gasoline and two-stroke oil) is stored. Pay attention to its condition, as cracks can cause leaks. * Fuel Cap: Seals the fuel tank and often includes a vent to prevent a vacuum from forming. A malfunctioning vent can cause fuel starvation. * Fuel Filter: Usually located inside the fuel tank, attached to the fuel line. It filters out debris to prevent it from clogging the carburetor. * Fuel Lines: These flexible hoses carry the fuel from the tank to the carburetor. They are prone to cracking and hardening over time. They are commonly made of a pliable material like Tygon. * Primer Bulb: A small rubber or plastic bulb that, when pressed, draws fuel from the tank and primes the carburetor for starting. If cracked, it will leak and can hinder starting. * Carburetor: This device mixes fuel and air in the correct proportions for combustion. It's a complex component with jets, needles, and diaphragms that require careful adjustment. Older models often have a simple design compared to newer, electronically controlled carburetors. The Carburetor is arguably the heart of the fuel system. * Impulse Line: While not a fuel line per se, the impulse line connects the crankcase to the carburetor and provides the pressure pulses needed to operate the fuel pump within the carburetor. A leak in this line can prevent the engine from starting or running properly.Symbols: Understanding the Diagram's Language

A fuel line diagram uses symbols to represent different components and their connections. Here's a breakdown of common symbols:

* Solid Lines: Typically indicate fuel lines. The thickness of the line might indicate the line's diameter, but this isn't always consistent. * Dashed Lines: Often represent the impulse line or vent lines. * Arrows: Indicate the direction of fuel flow. * Circles or Ovals: Can represent the fuel filter, primer bulb, or other small components. * Rectangles or Squares: Might represent the carburetor or fuel tank. * Color Coding: Some diagrams use color coding to distinguish between different types of lines (e.g., fuel line vs. impulse line). If present, a legend will explain the color scheme. * Component Labels: Each component should be clearly labeled with its name (e.g., "Fuel Tank," "Carburetor," "Fuel Filter").While variations exist, most diagrams adhere to these basic conventions.

How It Works: Fuel System Operation

The McCulloch chainsaw fuel system operates on a simple principle: drawing fuel from the tank and delivering it to the engine for combustion. Here's a step-by-step explanation:

1. Fuel is Drawn: As the engine runs, a vacuum is created in the carburetor. This vacuum draws fuel from the fuel tank through the fuel filter and into the carburetor. 2. Fuel Mixing: Inside the carburetor, the fuel is mixed with air in the correct proportions to create a combustible mixture. 3. Mixture Delivery: The fuel-air mixture is then drawn into the engine's cylinder, where it's ignited by the spark plug. 4. Impulse Line Operation: The impulse line transmits pressure pulses from the crankcase to the carburetor's fuel pump. These pulses actuate the pump, drawing fuel from the tank and delivering it to the carburetor's fuel bowl. The fuel pump is a crucial element that keeps the fuel flowing, especially under varying engine loads and orientations. 5. Venting: As fuel is consumed, a vacuum would form in the fuel tank, preventing fuel from flowing. The vent in the fuel cap or a dedicated vent line allows air to enter the tank, equalizing the pressure.Real-World Use: Basic Troubleshooting Tips

Here are some common problems and how to troubleshoot them using the fuel line diagram:

* Engine Won't Start: * Check Fuel Level: Obvious, but important! * Inspect Fuel Lines: Look for cracks, leaks, or kinks. Replace if necessary. * Check Fuel Filter: A clogged filter restricts fuel flow. Clean or replace it. * Prime the Carburetor: Use the primer bulb to ensure fuel is reaching the carburetor. If the bulb doesn't fill with fuel, there's a blockage somewhere. * Inspect Impulse Line: Check for cracks or leaks. Replace if damaged. * Engine Runs Poorly or Stalls: * Check Fuel Cap Vent: A blocked vent can cause fuel starvation. Try loosening the fuel cap slightly. * Carburetor Adjustment: The carburetor might need adjustment. Refer to the chainsaw's manual for instructions. * Fuel Line Air Leaks: Small cracks might allow air into the fuel lines, causing the engine to run lean. * Fuel Leakage: * Inspect Fuel Lines and Tank: Look for cracks or leaks. Replace damaged components. * Check Fuel Cap Seal: Make sure the fuel cap is sealing properly. * Carburetor Leakage: A leaking carburetor might need to be rebuilt.Safety Considerations

Working with fuel systems can be hazardous. Keep these safety precautions in mind:

* Work in a Well-Ventilated Area: Fuel vapors are flammable and can be harmful to breathe. * No Smoking or Open Flames: Keep all sources of ignition away from the work area. * Use Appropriate Tools: Use tools designed for fuel line work to avoid damaging components. * Wear Safety Glasses: Protect your eyes from fuel splashes. * Handle Fuel Carefully: Dispose of fuel-soaked rags properly to prevent fire hazards. * Fuel Lines close to the engine can become very hot, avoid contact immediately after use. * Carburetors, especially older ones, may contain asbestos. Use caution when disassembling and rebuilding.With a clear understanding of the McCulloch chainsaw fuel line diagram, you can confidently tackle fuel system issues and keep your saw running smoothly. Remember to always prioritize safety and consult the chainsaw's manual for specific instructions and recommendations.

We have a file containing the diagram and more technical details. Contact us to download the file and further assist you with your chainsaw repairs.