Mercruiser Alpha One Shift Cable Diagram

The Mercruiser Alpha One sterndrive is a workhorse of the boating world, known for its reliability and relatively simple design. But, like any mechanical system, it requires maintenance and occasional repairs. Understanding the shift cable system is crucial for smooth and safe operation. This article provides a detailed look at the Mercruiser Alpha One shift cable diagram, explaining its components, function, and how to use it for troubleshooting.

Purpose of the Shift Cable Diagram

Why bother with a shift cable diagram? Several reasons. First and foremost, it's indispensable for diagnosing and repairing shifting problems. A sticky shift, difficulty engaging gears, or a complete inability to shift can often be traced back to a problem with the shift cable or its associated components. Secondly, the diagram is invaluable when replacing the shift cable itself. It provides a visual guide for routing the new cable correctly, ensuring it doesn't bind or chafe. Furthermore, understanding the system allows you to make informed decisions about maintenance and prevent future problems. For example, knowing the location of lubrication points helps you keep the system operating smoothly. Finally, whether you're a seasoned DIYer or simply want to understand your boat better, the diagram provides a valuable visual aid to the entire shift mechanism.

Key Specs and Main Parts

The Alpha One shift system connects the shift lever in the boat to the lower unit of the outdrive, allowing you to select forward, neutral, or reverse. Here's a breakdown of the key components:

- Shift Lever/Control Box: Located in the boat, this is where you initiate the shifting process. It's mechanically linked to the shift cable.

- Shift Cable: This flexible cable transmits the motion from the shift lever to the shift mechanism on the engine. It's made of a steel cable encased in a protective sheath. Different Alpha One generations use slightly different cable lengths and end fittings.

- Remote Control Cable Bracket: Mounts the shift cable to the engine.

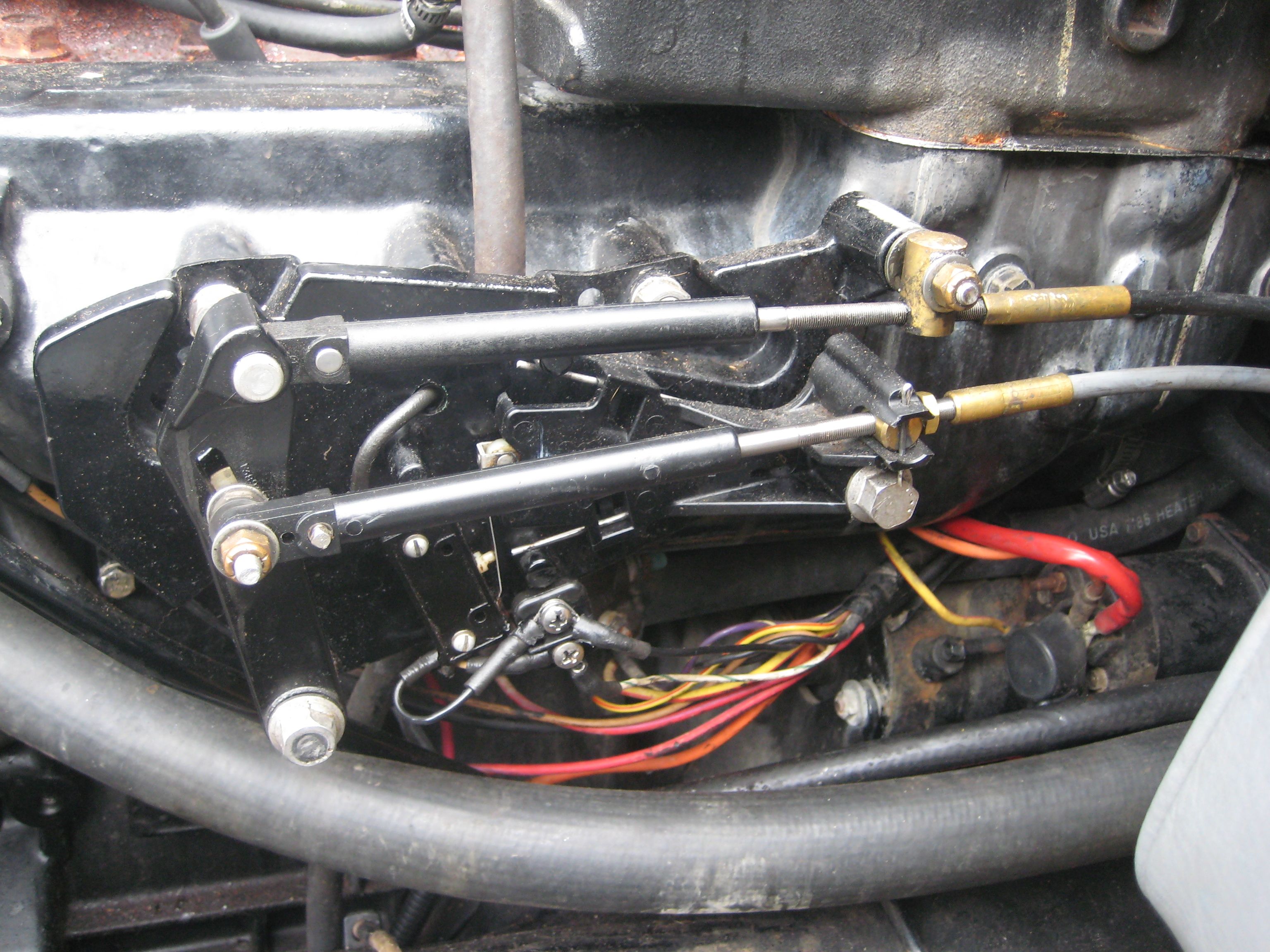

- Bellcrank Assembly (Shift Plate Assembly): This assembly is located on the engine. The shift cable connects to the bellcrank, which translates the linear motion of the cable into a rotary motion.

- Shift Shaft Linkage: Connects the bellcrank to the shift shaft.

- Shift Shaft: The shaft that runs down to the lower unit, actuating the clutch dog.

- Lower Shift Cable: A short cable connecting the upper shift shaft to the lower unit.

- Clutch Dog: Located in the lower unit, this component engages with the forward or reverse gear, transmitting power to the propeller.

Understanding the relationship between these components is crucial for interpreting the shift cable diagram. Key specifications to consider when replacing parts include cable length, end fitting type (threaded vs. quicksilver ball end), and whether the cable is designed for Gen I or Gen II Alpha One drives.

Understanding the Symbols

A shift cable diagram isn't just a random collection of lines and shapes; it uses specific symbols to represent different components and connections. Here's a guide to understanding the common symbols:

- Solid Lines: Typically represent the physical shift cable itself, or solid linkages like rods or shafts. The thickness of the line doesn't usually represent the actual size of the component.

- Dashed Lines: Often indicate a mechanical connection or linkage that is hidden from view or located behind other components.

- Arrows: Show the direction of movement or force transmission. For example, an arrow on the shift cable might indicate the direction the cable moves when shifting into forward.

- Circles/Dots: Can represent pivot points, mounting locations, or connection points.

- Rectangles/Squares: Often represent larger components like the shift control box or the bellcrank assembly.

- Color Coding (if present): While not always present on older diagrams, some diagrams use color coding to distinguish between different cables or linkages. For example, the upper shift cable might be represented in red, while the lower shift cable is blue.

Pay close attention to the legend or key that accompanies the diagram. It will explain the specific symbols used in that particular drawing.

How It Works: A Step-by-Step Explanation

The shift system works by converting the rotational motion of the shift lever into linear motion of the shift cable, which then actuates the clutch dog in the lower unit. Here's a simplified breakdown:

- You move the shift lever in the boat.

- This movement pulls or pushes the shift cable.

- The shift cable's movement rotates the bellcrank on the engine.

- The bellcrank's rotation moves the shift shaft linkage.

- The shift shaft rotates, transmitting motion down to the lower unit through the lower shift cable.

- In the lower unit, the rotation of the lower shift shaft actuates the shift mechanism and engages the clutch dog with either the forward or reverse gear (or neither for neutral).

The system relies on proper cable adjustment. If the cable is too loose or too tight, it won't accurately transmit the motion from the shift lever to the lower unit, leading to shifting problems. The cable's tension must be accurately set using the adjustment points along the cable.

Real-World Use: Basic Troubleshooting

The shift cable diagram is your best friend when troubleshooting shifting issues. Here are a few scenarios:

- Hard to Shift into Gear: Check the shift cable adjustment. Refer to the diagram to locate the adjustment points on the cable. Also, check for binding or corrosion in the shift cable. Look for kinks in the cable and lubricate all moving parts.

- Cannot Shift into Gear: Check the shift cable for breakage. Disconnect the cable at both ends and inspect for fraying or separation. Also check the bellcrank and shift shaft linkage for any signs of damage or disconnection. The shift cable diagram helps you identify all the connection points.

- Erratic Shifting: Look for wear or damage to the shift cable end fittings. The diagram will show you the type of fitting used on your specific Alpha One model. Also, check the condition of the bellcrank bushings. Worn bushings can introduce slack into the system, leading to erratic shifting.

If you suspect a problem with the lower unit, you'll likely need to consult a separate diagram specific to the lower unit's internal components.

Safety Considerations

Working on the shift system involves some inherent risks. Disconnecting the battery is always the first step before working on any electrical or mechanical system on a boat. The shift system includes:

- Sharp Edges: The bellcrank and shift shaft linkage can have sharp edges. Wear gloves to protect your hands.

- Moving Parts: Ensure the engine is off and the shift lever is in neutral before working on the shift system. Accidental engagement of the engine while working on the shift system can cause serious injury.

- Torque Specifications: When reassembling components, adhere to the manufacturer's torque specifications. Over-tightening bolts can damage components, while under-tightening can lead to loosening and failure.

If you are uncomfortable working on the shift system yourself, it's best to consult a qualified marine mechanic.

A well-maintained shift system ensures smooth and reliable operation of your Mercruiser Alpha One sterndrive. By understanding the shift cable diagram and following proper maintenance procedures, you can keep your boat shifting smoothly for years to come. We have a detailed shift cable diagram available for download that will help you visualize the system and troubleshoot issues more effectively. Contact us to request the file.