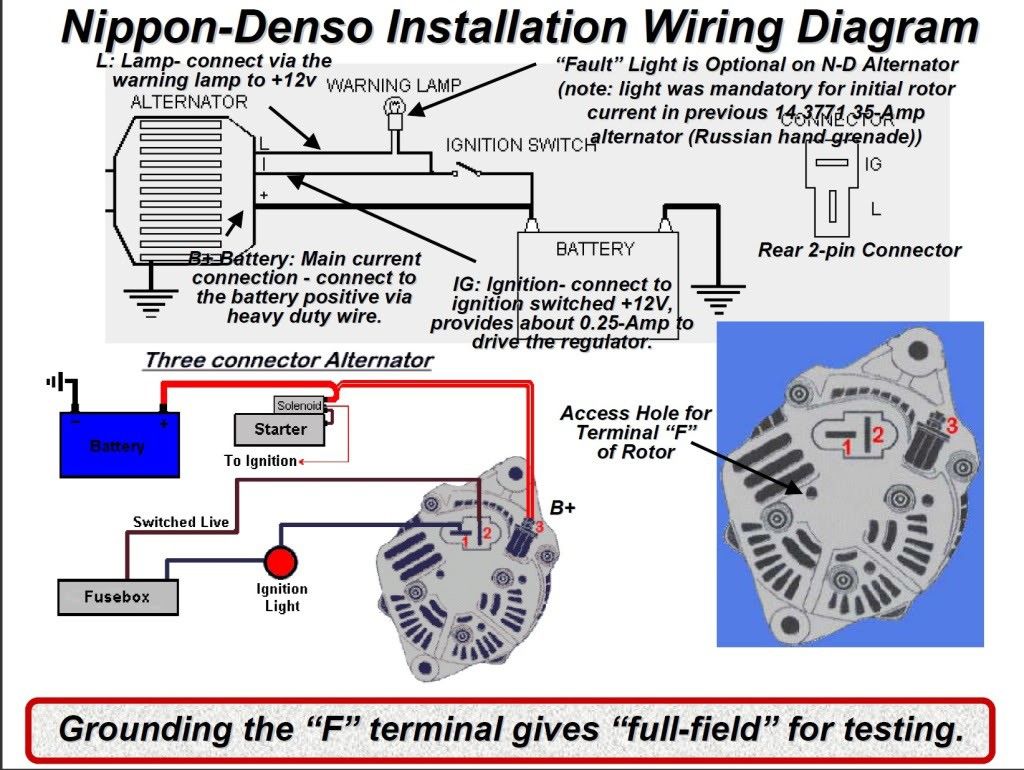

Three Wire Alternator Wiring Diagram

Understanding your car's charging system is crucial for reliable operation. While modern vehicles often employ complex charging systems managed by the ECU (Engine Control Unit), the fundamental three-wire alternator remains a staple in many vehicles, and understanding its wiring is essential for repairs, modifications, or even just satisfying your curiosity. This article will delve into the intricacies of the three-wire alternator wiring diagram, providing you with the knowledge to diagnose, troubleshoot, and even upgrade your charging system.

Purpose of Understanding the Three-Wire Alternator Wiring Diagram

Why bother learning about this diagram? There are several key reasons:

- Troubleshooting: When your battery isn't charging correctly, understanding the wiring helps you pinpoint the problem – is it the alternator itself, a faulty wire, a bad connection, or a blown fuse?

- Repair and Replacement: Replacing a damaged alternator requires correctly connecting the new unit. An incorrect wiring can damage the alternator or other electrical components.

- Upgrades and Modifications: Swapping in a higher-output alternator for increased electrical demands (e.g., aftermarket sound systems, off-road lighting) necessitates understanding how to integrate it into the existing wiring harness.

- Educational Value: Gaining a deeper understanding of your vehicle's electrical system empowers you to diagnose and fix issues yourself, saving you money and increasing your self-reliance.

Key Specs and Main Parts of a Three-Wire Alternator System

Before we dive into the wiring, let's define the key components and their specifications. The three-wire alternator gets its name from the three critical wires connected to it. The alternator is an electromechanical device that converts mechanical energy from the engine into electrical energy, which is used to charge the battery and power the vehicle's electrical systems.

Main Parts:

- Alternator: The heart of the system. Its output is typically rated in Amps (A), indicating its maximum current delivery capability. Common ratings range from 60A to 150A, but larger alternators are used for heavy-duty applications.

- Battery: A rechargeable energy storage device, usually a 12V lead-acid battery in most automotive applications.

- Voltage Regulator: Maintains a consistent voltage output from the alternator, typically around 13.8V to 14.4V, regardless of engine speed or load. In a three-wire system, the voltage regulator can be internal to the alternator, or it can be external and wired between the alternator and the battery.

- Wiring Harness: Connects all the components, transmitting electrical current and signals. Wire gauge (thickness) is crucial; too thin a wire can overheat and cause voltage drop.

- Fuses/Fusible Links: Protective devices that interrupt the circuit if excessive current flows, preventing damage to the system.

Key Specifications to Consider:

- Alternator Output (Amps): Should match or exceed the vehicle's electrical demands.

- Voltage Regulation Range: Should be within the battery's charging voltage specifications (typically 13.8-14.4V for a 12V system).

- Wire Gauge: Must be sufficient to handle the maximum current flow without excessive voltage drop. Use a wiring gauge calculator to determine the correct gauge based on current and wire length.

Symbols and Conventions in the Wiring Diagram

Wiring diagrams use standardized symbols to represent electrical components and connections. Understanding these symbols is vital for interpreting the diagram correctly.

- Lines: Represent wires. Solid lines indicate a direct connection, while dashed lines might indicate a shielded wire or a connection through a connector. The thickness of the line sometimes reflects wire gauge.

- Colors: Wires are often color-coded to aid in identification. Common colors include Red (positive), Black (ground), and various other colors for signal and control wires. The diagram will usually include a color code legend.

- Alternator Symbol: Typically a circle with an "ALT" or a stylized symbol representing the stator windings.

- Battery Symbol: A series of alternating long and short parallel lines.

- Voltage Regulator Symbol: A rectangle or square with "VR" or "REG" inside.

- Fuse Symbol: A zigzag line or a rectangle with a diagonal line through it.

- Ground Symbol: Usually a series of descending horizontal lines, representing a connection to the vehicle's chassis.

The diagram will also show connection points, often represented by dots where lines intersect. It's crucial to note that not all intersections indicate a connection; only those with a dot are electrically connected.

How the Three-Wire Alternator System Works

The three wires in this system serve distinct purposes:

- Battery (B+) or Output Terminal: This is the main output wire that connects directly to the positive (+) terminal of the battery. It carries the charging current from the alternator to the battery and provides power to the vehicle's electrical system. This wire is typically a heavy-gauge wire due to the high current it carries.

- Sense Wire (sometimes referred to as the Voltage Sense wire): This wire connects to a point in the electrical system that is representative of the system voltage, typically close to the battery or at the main power distribution block. It provides feedback to the voltage regulator about the actual voltage level in the system. The regulator then adjusts the alternator's output to maintain the desired voltage, compensating for voltage drops in the wiring. Connecting this wire directly to the alternator's B+ terminal will cause overcharging because the regulator only senses the alternator's voltage, not the voltage at the battery after voltage drop occurs along the main charging wire.

- Ignition or Exciter Wire (sometimes called the Indicator Lamp wire): This wire is connected to a switched 12V source, typically from the ignition switch. When the ignition is turned on, this wire provides a small current to "excite" the alternator's field windings, initiating the charging process. This wire also often connects to the dashboard indicator lamp (battery light). The battery light illuminates when the ignition is on and the alternator is not yet charging. Once the alternator starts producing voltage, the voltage on both sides of the lamp becomes equal, and the lamp turns off.

When the engine starts and the alternator begins to spin, the ignition wire provides the initial excitation. The alternator then generates AC (Alternating Current), which is converted to DC (Direct Current) by the rectifier diodes within the alternator. The voltage regulator monitors the system voltage via the sense wire and adjusts the alternator's output to maintain the desired charging voltage. The B+ wire delivers the charging current to the battery and the vehicle's electrical system.

Real-World Use: Basic Troubleshooting Tips

Here are some basic troubleshooting tips using the three-wire alternator wiring diagram:

- Battery Light Stays On: Check the exciter wire for continuity and voltage with the ignition on. If there's no voltage, trace the wire back to the ignition switch and check for blown fuses. Also, check the condition of your alternator.

- Low Battery Voltage: Check the B+ wire for a good connection at both the alternator and battery terminals. Measure the voltage drop across the B+ wire while the engine is running; excessive voltage drop indicates a poor connection or undersized wire. Verify that the voltage regulator is functioning correctly. Also, check the condition of your alternator.

- Overcharging: This is often caused by a faulty voltage regulator or an incorrectly connected sense wire. Ensure the sense wire is connected to a point representative of the system voltage, not directly to the alternator's B+ terminal.

- No Charging: Ensure the alternator belt is properly tensioned and not slipping. Check the B+ wire, sense wire and ignition wire connections at the alternator. Use a multimeter to check for continuity and voltage at the alternator terminals.

Safety Considerations

Working with automotive electrical systems can be dangerous. Always disconnect the negative (-) battery cable before working on the charging system to prevent short circuits and potential electrical shocks. The alternator's B+ terminal is a high-current source, so avoid touching it with any metal objects while the battery is connected. Be careful when working around the alternator belt, as it can cause serious injury if it catches clothing or body parts. When using a multimeter, be sure to set it to the correct voltage and current ranges to avoid damaging the meter or the vehicle's electrical system.

Important: When disconnecting and reconnecting the alternator, ensure the correct polarity is maintained. Reversing the polarity can damage the alternator and other electrical components.

With a better understanding of the three-wire alternator wiring diagram, you’re now equipped to tackle basic troubleshooting and repairs. Always double-check your work and consult a professional mechanic if you're unsure about any aspect of the charging system.

We have a downloadable version of the three-wire alternator wiring diagram available for your convenience. This resource will provide a visual aid for your repairs and modifications. Please contact us through the contact form for the download link.