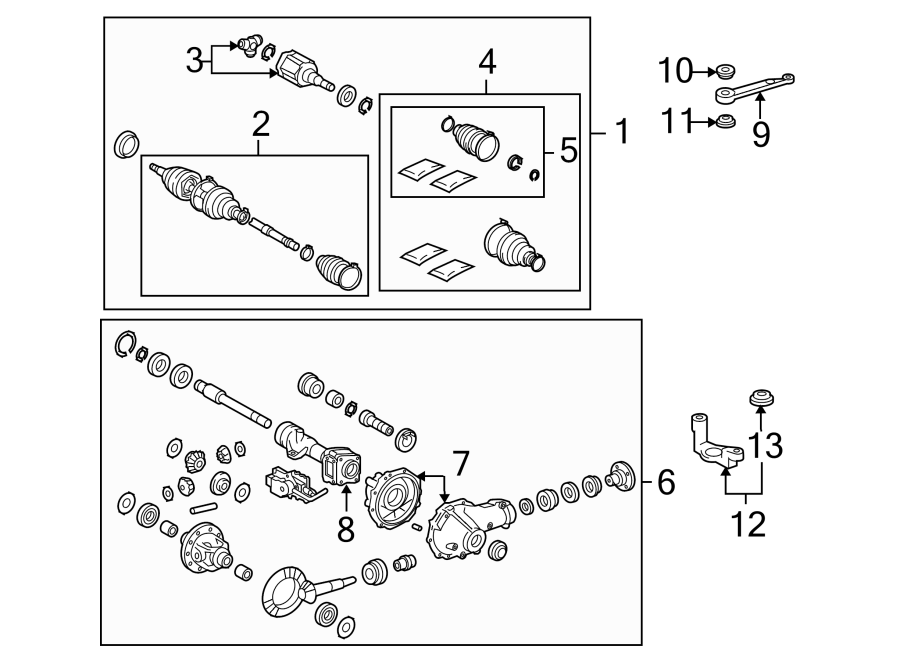

Toyota Tacoma Front Suspension Diagram

Alright, let's dive deep into the front suspension of the Toyota Tacoma. Understanding this system is crucial whether you're planning on tackling some DIY repairs, installing a lift kit, diagnosing a persistent clunk, or simply want to gain a deeper understanding of your truck. This article will walk you through a detailed front suspension diagram, explaining each component and its function in a way that’s both technically accurate and easy to understand.

Purpose of Understanding the Diagram

Why bother with a diagram? Well, it's your roadmap to the front suspension. A good diagram allows you to:

- Accurately Identify Parts: Knowing the correct names for each component is essential for ordering parts and communicating with mechanics.

- Diagnose Problems: The diagram helps visualize how the system is interconnected, making it easier to pinpoint the source of a problem.

- Plan Modifications: If you're considering lifting your Tacoma or upgrading suspension components, a diagram helps you understand the impact of these changes.

- Perform Repairs: Whether you're replacing ball joints or shocks, a diagram offers a clear reference for disassembly and reassembly.

- Increase Vehicle Knowledge: Gain a deeper knowledge and familiarity with your vehicle.

Key Specs and Main Parts

The Toyota Tacoma typically uses an independent front suspension (IFS) system, specifically a double-wishbone setup. This design offers a good balance between on-road comfort and off-road capability. Let's break down the main components:

- Upper Control Arm (UCA): The upper control arm connects the upper portion of the steering knuckle to the frame. It allows for vertical wheel movement while maintaining proper alignment. Aftermarket UCAs are frequently installed with lift kits to correct alignment geometry.

- Lower Control Arm (LCA): The lower control arm connects the lower portion of the steering knuckle to the frame. It's typically larger and more robust than the UCA and bears a significant amount of stress.

- Steering Knuckle (Spindle): The steering knuckle is the pivoting point that connects the wheel hub, bearings, and brake assembly to the suspension.

- Wheel Hub Assembly: This contains the wheel bearings and allows the wheel to rotate freely.

- Coilover Assembly: This combines the coil spring and shock absorber into a single unit. The coil spring provides the necessary support and ride height, while the shock absorber (damper) controls the spring's oscillations, preventing excessive bouncing.

- Coil Spring: Supports the vehicle's weight and determines ride height.

- Shock Absorber (Damper): Controls the movement of the spring, preventing excessive bouncing and maintaining tire contact with the road.

- Ball Joints: These are spherical bearings that connect the control arms to the steering knuckle, allowing for articulation. You'll find an upper ball joint and a lower ball joint on each side.

- Tie Rod Ends: Connect the steering rack to the steering knuckles, transmitting steering input to the wheels. There are inner and outer tie rod ends.

- Sway Bar (Stabilizer Bar): A torsion bar that connects the left and right sides of the suspension. It helps to reduce body roll during cornering.

- Sway Bar End Links: Connect the sway bar to the control arms.

- Bump Stops: Limit upward suspension travel, preventing damage to other components.

Understanding Diagram Symbols

Diagrams utilize symbols and conventions to convey information efficiently. Here's a breakdown of common elements:

- Solid Lines: Typically represent physical components like control arms, tie rods, and the frame.

- Dashed Lines: Often indicate hidden components or lines of action (e.g., the range of motion of a component).

- Arrows: Show the direction of movement or force. For example, an arrow pointing towards the coilover assembly indicates the direction of compression.

- Colors: Colors vary depending on the diagram, but they can be used to distinguish different systems or materials. For example, blue might represent hydraulic lines (if applicable to a system like X-REAS) and red might indicate high-stress areas.

- Icons: Icons may represent specific components or features. For example, a small circle with a line through it might represent a grease fitting (zerk fitting).

- Torque Specifications: These are critical! The diagram or accompanying documentation will usually list the torque specifications for each bolt and nut. Always use a torque wrench and adhere to these specifications.

- Part Numbers: Critical for ordering the correct replacement parts. These are often located near the component in the diagram.

It's crucial to consult the specific diagram for your Tacoma's year and trim level, as there may be slight variations.

How It Works

The Tacoma's front suspension is designed to allow the wheels to move independently, providing a smoother ride and better handling compared to a solid axle. Here's a simplified explanation of how it all works:

- Impact Absorption: When the wheel encounters a bump, the suspension system absorbs the impact. The coil spring compresses, storing energy.

- Damping: The shock absorber dampens the oscillation of the spring, preventing the wheel from bouncing excessively. It converts the kinetic energy of the suspension movement into heat, which is then dissipated.

- Wheel Movement: The control arms allow the wheel to move vertically, maintaining a relatively constant camber angle. This helps to keep the tire in contact with the road for optimal traction.

- Steering Input: When you turn the steering wheel, the steering rack pushes or pulls on the tie rod ends, which in turn rotate the steering knuckles, causing the wheels to turn.

- Sway Bar Action: During cornering, the sway bar resists body roll by transferring force from one side of the suspension to the other.

Real-World Use: Basic Troubleshooting Tips

Here are some common front suspension problems and how the diagram can help you diagnose them:

- Clunking Noise: Could be worn ball joints, tie rod ends, sway bar end links, or loose bolts. Use the diagram to inspect these components for play or damage.

- Squeaking Noise: Often caused by dry or worn-out bushings. Inspect the control arm bushings and sway bar bushings.

- Vibrations: Can be caused by unbalanced tires, worn wheel bearings, or damaged suspension components. Check the wheel hub assembly and ball joints.

- Poor Handling: May indicate worn shocks, damaged springs, or misalignment. Inspect the coilover assembly and control arms.

- Uneven Tire Wear: Often a sign of misalignment. The diagram won't directly diagnose this, but understanding the suspension geometry will help you understand how alignment adjustments affect tire wear.

Pro Tip: Before starting any work, take pictures of the suspension components. This will help you remember how everything goes back together.

Safety Considerations

Working on the front suspension can be dangerous due to the high spring forces and potential for components to suddenly release. Keep these points in mind:

- Spring Compression: Never disassemble a coilover assembly without using a proper coil spring compressor. These springs store a tremendous amount of energy and can cause serious injury or death if released improperly.

- Jacking and Support: Always use jack stands to support the vehicle after lifting it with a jack. Never work under a vehicle supported only by a jack.

- Torque Specifications: Adhere to all torque specifications when reassembling the suspension. Overtightening or undertightening bolts can lead to component failure.

- Wheel Alignment: After performing any major suspension work, have the vehicle professionally aligned.

- Brake Lines: Be extremely careful not to damage the brake lines while working on the suspension. Damaged brake lines can lead to brake failure.

- Personal Protective Equipment (PPE): Wear safety glasses and gloves to protect yourself from flying debris and harsh chemicals.

High risk components that should be handled with caution: The coil spring and brake lines.

By understanding the components, how they work together, and the potential hazards, you'll be better equipped to tackle any Tacoma front suspension project. Remember to always consult your vehicle's service manual for specific instructions and torque specifications.

You've made it this far! We have the front suspension diagram available for download. With the file in hand, you'll have a detailed visual aid to guide you through your Tacoma suspension projects. Good luck, and happy wrenching!