Vehicle Ignition Coils Suzuki Aerio Spark Plugs Diagram Diagram

Understanding the ignition system in your Suzuki Aerio is crucial for maintaining optimal engine performance and addressing potential issues. This article will guide you through the ignition coil and spark plug diagram specific to the Aerio, empowering you with the knowledge to diagnose problems, perform repairs, and potentially even upgrade your system. We'll break down the diagram's components, explain how they work together, and provide practical troubleshooting tips. We even have a high-resolution diagram available for download.

Why You Need This Diagram

The ignition system diagram is your roadmap for understanding the Aerio's spark delivery process. It's not just a pretty picture; it's a vital tool for:

- Troubleshooting Ignition Problems: Misfires, rough idling, and starting difficulties often stem from issues within the ignition system. The diagram helps pinpoint the source.

- Performing Repairs: Replacing ignition coils, spark plugs, or wiring? The diagram ensures you connect everything correctly.

- Upgrading Your Ignition System: Looking to improve performance with aftermarket coils or plugs? Understanding the existing configuration is essential.

- General Maintenance: Familiarizing yourself with the system's layout can help you identify potential problems before they become major headaches.

Key Specs and Main Parts: Suzuki Aerio Ignition System

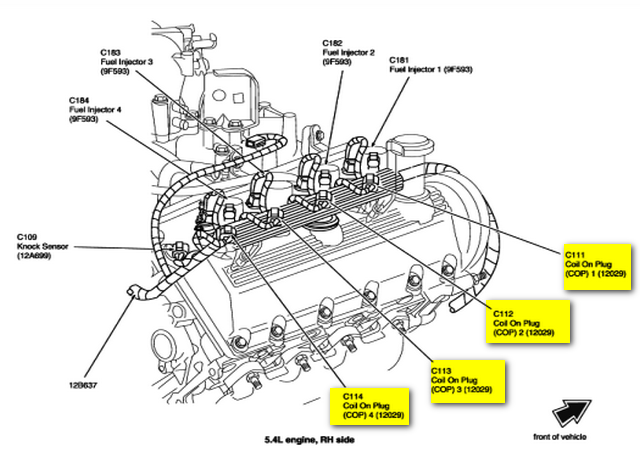

The Suzuki Aerio, depending on the year, will typically have either a coil-on-plug (COP) system or a distributor-based system with a single coil. Let's focus on the common COP configuration, as it's prevalent in many modern Aerios. A distributor-based system works by using a single coil to fire all cylinders, routing the high voltage through a distributor to each spark plug. A COP system, however, is more efficient.

Key components include:

- Ignition Coils: Each coil is responsible for generating the high-voltage spark needed to ignite the air-fuel mixture in one cylinder. They are usually mounted directly on top of the spark plugs. The Aerio will typically have four coils, one for each cylinder in its inline-4 engine.

- Spark Plugs: These devices receive the high-voltage electricity from the coils and create a spark across a gap, initiating combustion. Spark plugs are rated by their heat range, which indicates their ability to dissipate heat. Using the wrong heat range can lead to pre-ignition, detonation, or fouling. Consult your owner's manual or a reputable parts supplier for the correct spark plug type for your Aerio.

- Wiring Harness: The wiring harness connects the ignition coils to the Engine Control Unit (ECU) and provides power and control signals.

- Engine Control Unit (ECU): The ECU controls the timing and duration of the spark, based on various engine parameters.

- Crankshaft Position Sensor (CKP): This sensor provides the ECU with information about the engine's speed and position, which is critical for timing the ignition.

- Camshaft Position Sensor (CMP): This sensor provides the ECU with information about the camshaft's position, which is used for determining which cylinder is on its compression stroke.

Diagram Symbols: Decoding the Visual Language

Understanding the symbols on the diagram is crucial for interpreting its information.

- Solid Lines: These typically represent wires carrying electrical current. The thickness of the line might indicate the gauge (size) of the wire.

- Dashed Lines: These often indicate a ground connection or a shielded wire.

- Color Codes: Wires are often color-coded to identify their function. For example, a red wire might indicate a power supply, while a black wire typically indicates a ground. The diagram will usually include a key to the color codes used. Common colors include Red (power), Black (ground), and various other colors indicating specific signal wires.

- Component Symbols: Each component, such as the ignition coil, spark plug, and sensors, will have a specific symbol representing it. These symbols are standardized across many diagrams.

- Ground Symbol: This symbol (often resembling an upside-down tree or a series of decreasing lines) indicates a connection to the vehicle's chassis ground.

- Connectors: Connectors are often depicted as small squares or rectangles, indicating where wires are joined together.

How It Works: The Ignition Sequence

The ignition system's operation is a carefully choreographed sequence:

- The ECU receives signals from the crankshaft and camshaft position sensors.

- Based on these signals, the ECU determines the correct timing for the spark.

- The ECU sends a signal to the appropriate ignition coil.

- The ignition coil, which is essentially a transformer, increases the voltage from the battery (typically 12 volts) to a very high voltage (typically 20,000-40,000 volts).

- This high-voltage electricity is sent to the spark plug.

- The high voltage overcomes the resistance of the spark plug gap, creating a spark.

- The spark ignites the air-fuel mixture in the cylinder, initiating combustion and driving the piston down.

This process is repeated for each cylinder in the engine, in the firing order specified by the manufacturer. The ECU precisely controls the timing of the spark to optimize engine performance and fuel efficiency. A fault in any part of this system, from a bad sensor to a worn-out spark plug, can disrupt the combustion process and cause engine problems.

Real-World Use: Basic Troubleshooting Tips

Here are a few basic troubleshooting tips you can use with the diagram:

- Misfires: If you're experiencing misfires, use a scan tool to identify which cylinder is misfiring. Then, inspect the corresponding ignition coil and spark plug. Check the wiring and connectors for any damage or corrosion. Consult the diagram to verify the wiring connections are correct.

- No Spark: If you suspect a complete lack of spark, use a spark tester to verify that the ignition coils are producing a spark. If no spark is present, check the power supply to the coils and the signal wires from the ECU. Use the diagram to trace the circuit and identify potential faults.

- Rough Idling: Rough idling can be caused by a variety of factors, including faulty spark plugs or ignition coils. Inspect the spark plugs for wear, damage, or fouling. Check the coil's resistance.

- Check Engine Light (CEL): A CEL related to the ignition system will often have codes related to misfires, coil issues, or sensor problems. Use the diagram to aid in checking the wiring and proper voltage at the suspected failing part.

Remember to always consult your vehicle's service manual for specific troubleshooting procedures and torque specifications.

Safety: High Voltage Hazards

The ignition system generates extremely high voltage, which can be lethal.

- Never work on the ignition system with the engine running or the ignition switch turned on.

- Always disconnect the negative battery cable before working on the ignition system.

- Use caution when handling spark plugs and ignition coils, as they may retain a residual charge even after the engine is turned off.

- Do not touch any exposed wires or connectors while the ignition system is energized.

- If testing for spark, use an insulated spark tester to prevent electric shock.

Download the Diagram

We have a detailed Suzuki Aerio ignition coil and spark plug diagram available for download to aid in your troubleshooting and repair endeavors. Having it available will make referencing the color codes and wiring paths a much more straightforward process.