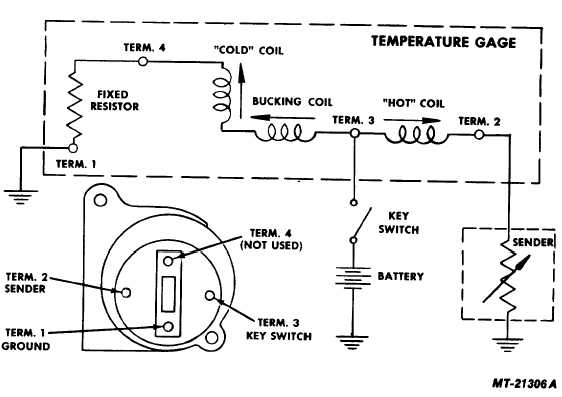

Water Temperature Gauge Wiring Diagram

Let's dive into the world of water temperature gauge wiring diagrams. If you're an experienced DIYer, a modder, or even a budding mechanic, understanding this diagram is crucial for repairs, modifications, or simply gaining a deeper understanding of your car's cooling system. We'll break it down in a way that's technically sound but also easy to grasp.

Purpose: Why Bother?

Why should you care about a water temperature gauge wiring diagram? Several reasons:

- Troubleshooting: When your temperature gauge acts erratic, shows incorrect readings, or doesn't work at all, the diagram is your roadmap for diagnosing the issue.

- Installation: Installing an aftermarket gauge? You need the wiring diagram to connect it correctly to the sensor and power source.

- Modification: Rewiring or upgrading your cooling system often involves working with the temperature sensor and gauge circuits.

- Learning: Simply understanding how the system works gives you a better handle on your car's overall health.

Key Specs and Main Parts

Before we dissect the diagram, let's identify the main players:

- Temperature Sensor (or Sender): This is the device that sits in the engine block (usually near the thermostat housing) and measures the engine coolant temperature. It's typically a thermistor, a type of resistor whose resistance changes with temperature.

- Temperature Gauge: Located on your dashboard, this is the instrument that displays the coolant temperature reading to you. It's essentially a voltmeter calibrated to display temperature instead of voltage.

- Wiring Harness: The network of wires connecting the sensor, gauge, and power source. This is where things can get tricky.

- Power Source: Usually a 12V DC supply from the car's electrical system.

- Ground Connection: Essential for completing the electrical circuit. A bad ground can cause all sorts of problems.

Key Specs to Consider:

- Voltage: The gauge and sensor are typically designed to operate on 12V DC in most vehicles.

- Resistance Range: The sensor's resistance will vary depending on the coolant temperature. The gauge is calibrated to interpret these resistance changes as temperature. This will be specific to your sensor and gauge, so consult the manufacturer's documentation.

- Wire Gauge: The thickness of the wires used in the circuit. Using the correct gauge is crucial to prevent voltage drops and overheating. Generally, 18-20 gauge wire is sufficient for this application, but always check the specific requirements.

- Sensor Type: Knowing if your sensor is a sending unit to control the factory gauge, or a sending unit used to interface with an aftermarket computer/data logger is very important.

Symbols: Deciphering the Language

Wiring diagrams use standardized symbols to represent electrical components. Here's a breakdown of the most common ones you'll encounter:

- Straight Lines: Represent wires. Thicker lines usually indicate wires carrying higher current.

- Dotted Lines: Often represent connections to ground (chassis ground).

- Colored Lines: Each color represents a specific wire and its function. Refer to the diagram's legend to understand the color codes. Common colors include:

- Red: Often indicates power (positive).

- Black: Usually indicates ground (negative).

- Green, Yellow, Blue: Often used for signal wires (e.g., from the sensor to the gauge).

- Resistor Symbol (Zigzag Line): Represents a resistor. In our case, it can represent the temperature sensor itself.

- Ground Symbol (Downward-Pointing Triangle or Stacked Lines): Indicates a connection to ground.

- Gauge Symbol (Circle with a Needle): Represents the temperature gauge.

- Connectors (Circles or Squares where Lines Meet): Indicate where wires are connected together.

- Fuses (Small Rectangle with a Line Through It): Protection device, make sure they are adequate for the circuit.

Understanding these symbols is essential for tracing the circuit and identifying potential problem areas.

How It Works: From Sensor to Gauge

Here's how the water temperature gauge system typically works:

- Sensing the Temperature: The temperature sensor, located in the engine block, measures the coolant temperature. As the temperature changes, the sensor's resistance changes.

- Sending the Signal: The sensor sends an electrical signal (a change in resistance) through a wire to the temperature gauge.

- Interpreting the Signal: The temperature gauge receives the signal and interprets it as a temperature reading. It then displays this reading on the dashboard.

- Completing the Circuit: A ground wire provides a return path for the electrical current, completing the circuit.

The gauge itself is essentially a voltmeter that's been calibrated to display temperature. It measures the voltage drop across the sensor and translates that voltage into a temperature reading.

Real-World Use: Basic Troubleshooting Tips

Let's say your temperature gauge is acting up. Here's how you can use the wiring diagram to troubleshoot:

- No Reading:

- Check the Fuse: Locate the fuse for the temperature gauge circuit and make sure it's not blown. The wiring diagram will show you which fuse to check.

- Check the Ground: A bad ground is a common culprit. Make sure the ground connection for the gauge is clean and secure. Use the diagram to locate the ground point.

- Check the Sensor: Disconnect the sensor and test its resistance using a multimeter. Compare the reading to the manufacturer's specifications for the sensor's resistance at different temperatures.

- Check the Wiring: Use the diagram to trace the wiring from the sensor to the gauge. Look for any breaks, shorts, or corrosion in the wires or connectors.

- Erratic Reading:

- Check the Sensor: As above, test the sensor's resistance.

- Check the Wiring: Look for loose connections or frayed wires that could be causing intermittent signals.

- Check the Gauge: In some cases, the gauge itself may be faulty. This is harder to diagnose without specialized equipment.

- Overheating Indication with Cool Engine:

- Check the Wiring: A short to ground in the sensor wire can cause the gauge to read high even when the engine is cool.

- Check the Sensor: A failed sensor could be sending an incorrect signal.

Remember to always consult your car's service manual for specific instructions and troubleshooting procedures.

Safety: Highlighting Risky Components

Working with electrical systems can be dangerous. Here are some safety precautions to keep in mind:

- Disconnect the Battery: Before working on any electrical components, disconnect the negative terminal of the battery to prevent accidental shocks or shorts.

- Work in a Well-Ventilated Area: If you're working with gasoline or other flammable fluids, make sure the area is well-ventilated to prevent explosions.

- Use Proper Tools: Use insulated tools designed for electrical work.

- Avoid Water: Never work on electrical systems in wet conditions.

- Be Careful with 12V Power: While 12V DC isn't lethal, it can still deliver a painful shock. Avoid touching exposed wires.

- Especially Watch for Short Circuits: A short circuit is dangerous. It can damage components and cause fires. Always double-check your wiring before reconnecting the battery.

Specific to this circuit: The temperature sensor wire can sometimes be located near hot engine components. Be cautious when working around these areas to avoid burns.

Understanding your water temperature gauge wiring diagram is a powerful tool for maintaining and modifying your car. With a little knowledge and the right tools, you can diagnose problems, install new gauges, and gain a deeper understanding of your vehicle's cooling system.

Ready to take the next step? We have a basic wiring diagram file available for download that covers the general principles discussed here. Remember to always refer to the specific diagram for your vehicle's year, make, and model.