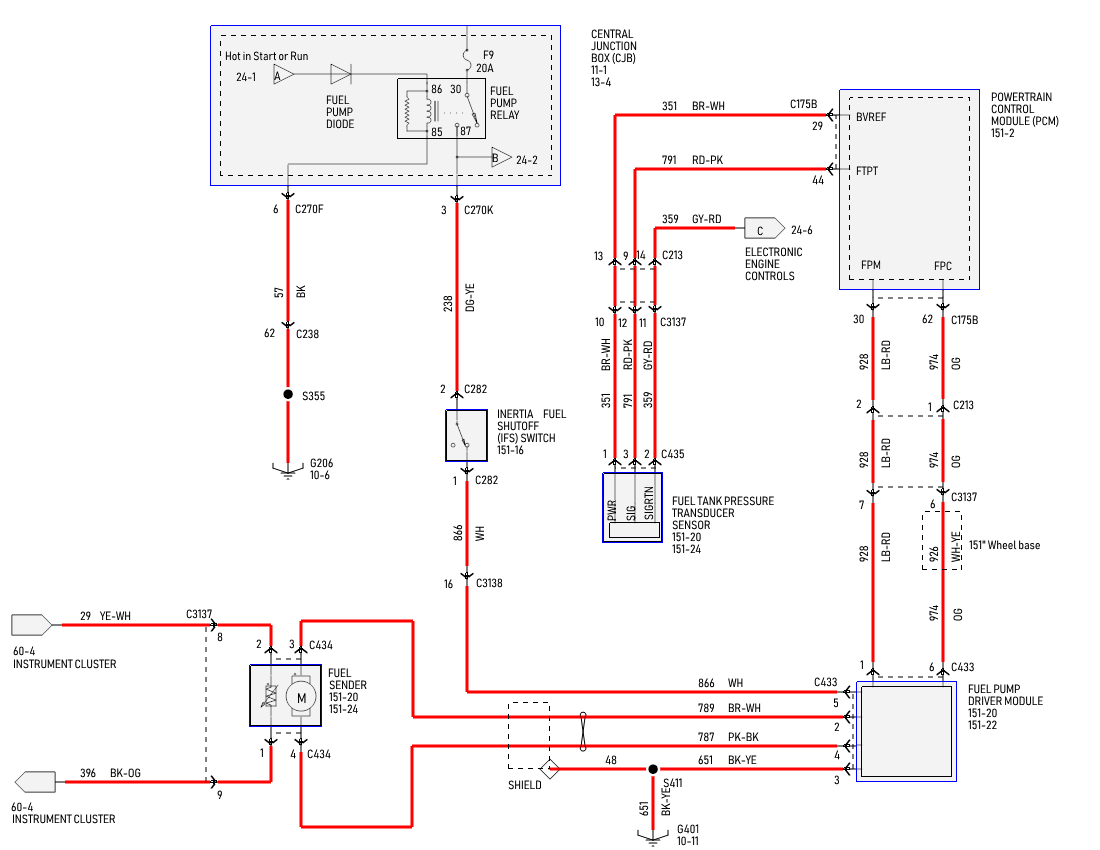

Wiring Diagram Ford Fuel Pump Driver Module Bypass

Let's talk about bypassing the Fuel Pump Driver Module (FPDM) on your Ford. This is a procedure that can be useful for troubleshooting fuel pump issues, potentially getting your vehicle running in a pinch, or for specific performance applications. However, it's crucial to understand the implications and potential risks before proceeding. This article provides a detailed wiring diagram explanation to help you understand the process. Keep in mind that *bypassing the FPDM should be considered a temporary solution* unless you fully understand the long-term consequences for your specific application.

Purpose of a Fuel Pump Driver Module Bypass

Why would you even consider bypassing the FPDM? There are several scenarios where this might be considered:

- Troubleshooting: If you suspect a faulty FPDM, bypassing it can help you determine if the module is indeed the problem. By directly powering the fuel pump, you eliminate the FPDM as a potential culprit.

- Temporary Repair: If your FPDM fails while you're on the road, a bypass can potentially get you home. This is strictly a temporary measure.

- Performance Applications: In some high-performance setups, especially when upgrading to a larger fuel pump, enthusiasts might choose to bypass the FPDM to ensure a constant voltage supply to the pump. This is often done in conjunction with a more robust aftermarket fuel pump controller, and it's not recommended for a stock fuel system.

- Learning and Understanding: Studying the bypass wiring and how it impacts the fuel system is a great way to learn about your vehicle's electrical architecture.

It's essential to understand that the FPDM is designed to control the fuel pump's speed based on engine demand. Bypassing it typically results in the fuel pump running at 100% capacity all the time. This can lead to:

- Increased Fuel Pressure: Running the pump at full speed constantly increases fuel pressure, which can overwhelm the fuel pressure regulator and potentially damage other fuel system components.

- Reduced Fuel Pump Lifespan: Running the pump at full speed continuously can shorten its lifespan due to increased wear and tear.

- Potential Fuel Leaks: Excessive fuel pressure can lead to leaks in the fuel lines or injectors.

- Driveability Issues: Constant high fuel pressure can lead to rich running conditions, negatively impacting engine performance and fuel economy.

Key Specs and Main Parts

Before diving into the diagram, let's define the key components involved:

- Fuel Pump Driver Module (FPDM): This module controls the voltage supplied to the fuel pump, regulating its speed based on signals from the PCM (Powertrain Control Module).

- Fuel Pump: The electric pump located inside the fuel tank that delivers fuel to the engine.

- PCM (Powertrain Control Module): The "brain" of the engine, responsible for managing various engine functions, including fuel delivery.

- FP Relay (Fuel Pump Relay): A relay that provides power to the FPDM.

- Battery: The vehicle's main power source.

- Ground (Chassis Ground): The negative terminal of the vehicle's electrical system, usually connected to the chassis.

- Wiring: The conductors that carry electrical current between the components. Wire gauge (thickness) is critical; ensure you use appropriately sized wire to handle the fuel pump's current draw.

- Fuse: A safety device that protects the circuit from overcurrent. Always use the correct amperage fuse.

Symbols, Lines, Colors, and Icons

Understanding the symbols used in the wiring diagram is crucial for proper interpretation. Here's a breakdown of common symbols:

- Solid Lines: Represent wires connecting different components. The thickness of the line may represent the gauge of the wire.

- Dashed Lines: Usually indicate signal wires or control wires with lower current.

- Colors: Each color typically represents a specific wire function. Common colors include Red (power), Black (ground), and various other colors for signals and data. The wiring diagram you download will include a color code legend.

- Battery Symbol: A standard battery symbol indicates the power source.

- Ground Symbol: A three-tiered inverted triangle indicates a connection to the chassis ground.

- Relay Symbol: A square with a coil and switch inside represents a relay. The coil is the electromagnet, and the switch connects or disconnects the circuit.

- Fuse Symbol: A wavy line inside a rectangle represents a fuse.

- Connector Symbol: A rectangle with lines indicates a connector where wires are joined.

Wire colors are standardized but can vary slightly between Ford models and years. The downloaded diagram will have a detailed color code key specific to that vehicle configuration. For example, a Red wire might be the main power feed, while a Black wire represents ground. A Brown wire may carry a signal from the PCM to the FPDM.

How It Works (FPDM Bypass)

The basic principle of bypassing the FPDM involves disconnecting the fuel pump from the FPDM output and directly supplying power to it. Here's a simplified overview:

- Identify the Fuel Pump Power Wire: Locate the wire that provides power from the FPDM to the fuel pump. This is usually accessible at the FPDM connector or near the fuel pump itself.

- Disconnect the FPDM Output: Disconnect this wire from the FPDM output. It is critical to properly insulate the disconnected FPDM wire to prevent short circuits.

- Provide Direct Power: Run a new wire from a suitable 12V power source (often directly from the battery or an appropriate fused source) to the fuel pump's power wire. Important: This new wire *must* be properly fused with a fuse rated to handle the fuel pump's maximum current draw. Refer to your fuel pump's specifications for the correct fuse size. Use a wire gauge that is adequate for the current; 12 or 14 gauge is typically sufficient, but larger pumps may require heavier gauge wiring.

- Ensure Proper Ground: The fuel pump needs a good ground connection. Verify the existing ground is secure, or run a new ground wire to a known good chassis ground.

The downloaded wiring diagram illustrates these steps with specific wire colors and connection points for your vehicle. Note that proper connections are absolutely critical. Poor connections can lead to voltage drops and overheating, which can damage the fuel pump or cause a fire.

Real-World Use – Basic Troubleshooting Tips

Here are a few troubleshooting tips related to FPDM bypass:

- Fuel Pump Doesn't Run After Bypass: Double-check all connections, including the ground. Verify the fuse in the bypass circuit is intact. Test the fuel pump directly by applying 12V directly to its terminals (after disconnecting it from the wiring harness). If it still doesn't run, the fuel pump itself may be faulty.

- Engine Runs Rich: This is a common symptom of bypassing the FPDM, as the pump is running at full speed constantly. A fuel pressure regulator issue could be the underlying cause.

- Fuel Leak: Inspect fuel lines and fittings for leaks, especially after increasing the fuel pressure by bypassing the FPDM.

- Check Engine Light: Bypassing the FPDM can trigger check engine lights related to fuel trim or fuel pump control. A scan tool can help diagnose the specific code.

Safety – Highlight Risky Components

Working with fuel systems is inherently dangerous. Gasoline is highly flammable, and electrical sparks can ignite it. Here are some key safety precautions:

- Disconnect the Battery: Always disconnect the negative battery terminal before working on any electrical components.

- Work in a Well-Ventilated Area: Gasoline fumes can be harmful and explosive.

- No Smoking or Open Flames: Keep all sources of ignition away from the work area.

- Use Proper Tools: Use insulated tools to prevent short circuits.

- Wear Safety Glasses: Protect your eyes from fuel splashes.

- Have a Fire Extinguisher Nearby: Be prepared for a fire emergency.

- Fuel Lines are Pressurized: Before disconnecting any fuel lines, relieve the fuel pressure. Consult your vehicle's service manual for the proper procedure.

- Avoid Damaging Fuel Lines: Be careful not to kink or damage fuel lines, as this can cause leaks.

- Proper Insulation: Ensure all connections are properly insulated to prevent short circuits.

The fuel pump and fuel lines are under pressure. Improper handling can result in serious injury.

This article provides a general overview of FPDM bypass. The specific wiring and procedures can vary depending on the Ford model and year. Always consult the specific wiring diagram for your vehicle, which you can download below.

Download the detailed wiring diagram for FPDM bypass [hypothetical download link here].